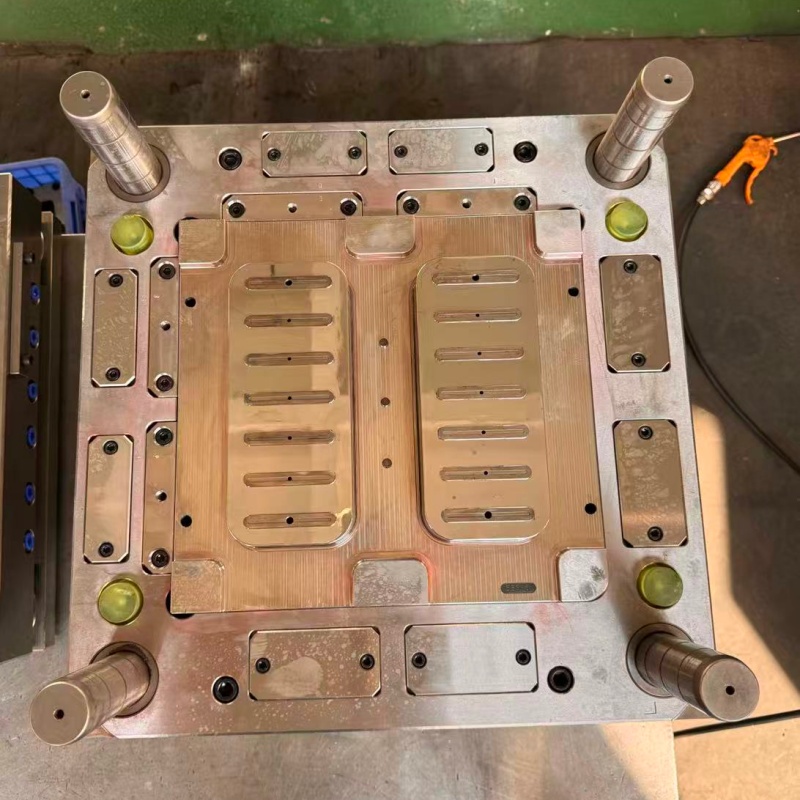

injection mold design and production by fengjin mold industry in xiamen,China

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:14

Introduction to Plastic Molds for Electronic Accessories

Plastic molds are the core manufacturing tool for producing high-precision plastic components of electronic accessories, widely applied in crafting parts like phone cases, charger housings, earphone shells, and connector insulators. Tailored to the strict requirements of the electronics industry, these molds are engineered to achieve ultra-fine dimensional accuracy, smooth surface finishes, and consistent product quality, ensuring seamless compatibility with electronic components.

We specialize in designing and manufacturing custom plastic molds for electronic accessories, integrating advanced CAD/CAM technologies and precision machining processes such as CNC milling and EDM (Electrical Discharge Machining) to meet complex part geometries. Our molds adopt a modular structure, featuring interchangeable inserts that enable flexible production of multiple product variants, effectively reducing mold development cycles and production costs.

In terms of material selection, we utilize high-performance mold steels like S136 and H13, which offer excellent wear resistance, corrosion resistance, and thermal stability, extending the mold service life to over 1 million shots for mass production scenarios. We also prioritize the integration of cooling system optimization in mold design, with evenly distributed cooling channels that accelerate plastic solidification, shorten injection molding cycles, and minimize product warpage and deformation.

Our electronic accessory plastic molds fully comply with international industry standards, including RoHS and REACH, ensuring that the molded plastic parts are free of harmful substances and meet the environmental requirements of global electronic markets. Whether for consumer electronics, industrial electronics, or automotive electronics applications, we can provide one-stop mold solutions from design and prototyping to mass production, helping clients to launch high-quality electronic accessories efficiently and gain a competitive edge in the market.

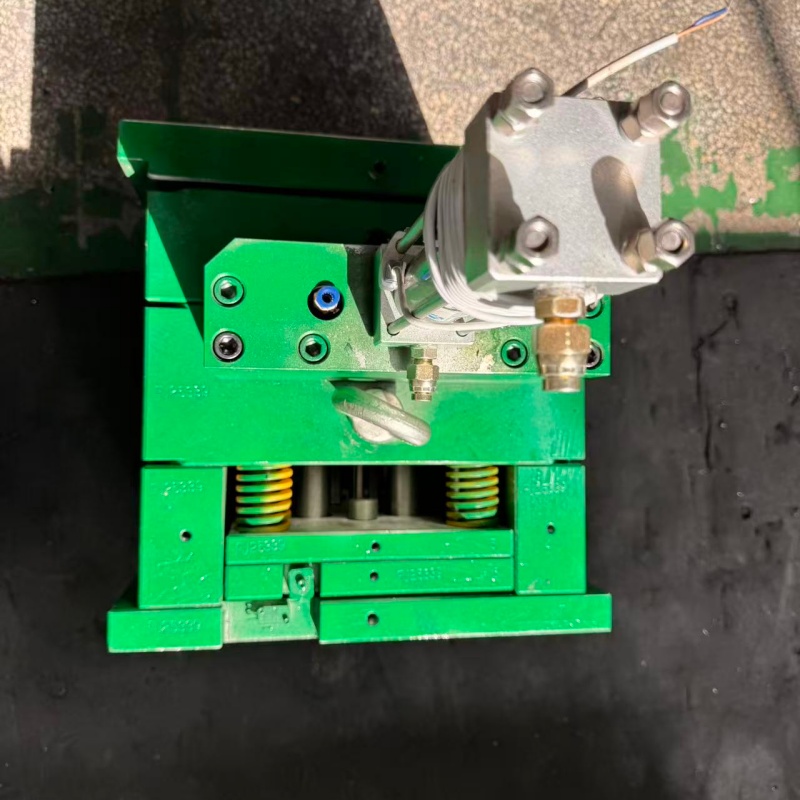

We'll spray color on mold surface for rust protection before delivery

part of the working area by cnc in our factory

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | mould manufacturer | 14 | S136 | 45# | 45days | 400000 | 40 |

Other plastic injection mould products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom.