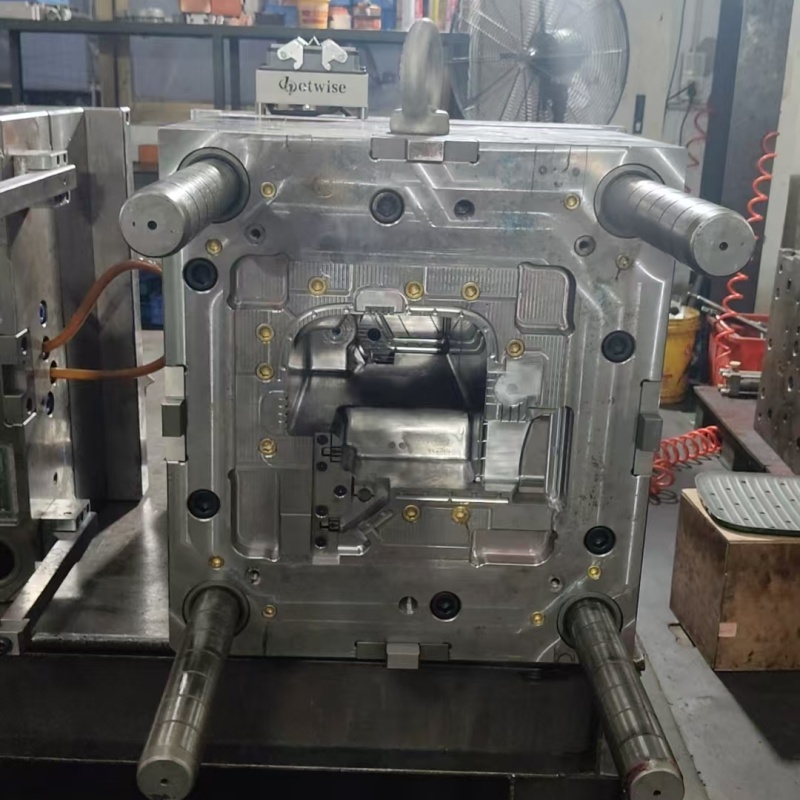

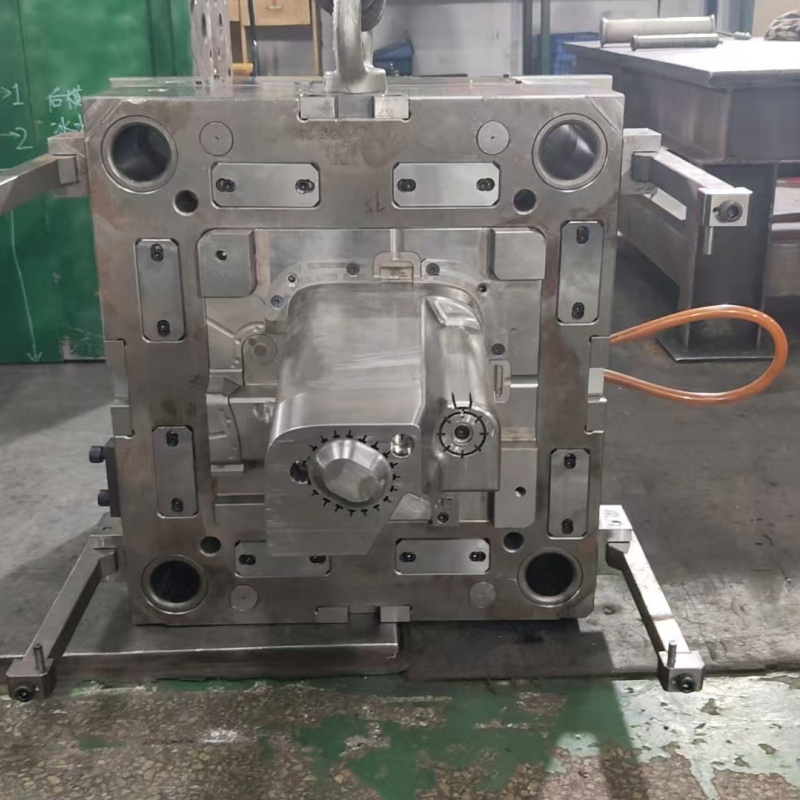

Mold For The Plastic Cover Of The Smart Toilet Remote Control

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:4

Delivery Time:45days for mold trail test

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding | 4 | S136 | 45# | 45days | 400000 | 40 |

Here is a detailed description of the manufacturing process for a smart toilet remote control housing mold, written in English.

The Manufacturing Process of a Smart Toilet Remote Control Housing Mold

The creation of a high-quality plastic housing for a smart toilet remote control begins with the precision engineering and fabrication of an injection mold. This mold is a complex tool that must meet exacting standards for durability, precision, and surface finish. The process involves several critical stages, from initial design to final quality assurance.

1. Design and Engineering (DFM - Design for Manufacturability)

The process starts long before metal is cut. Using the 3D CAD model of the remote control housing provided by the product designer, mold engineers analyze the part for manufacturability.

* **Part Analysis:** They examine wall thickness uniformity, identify potential sink marks, and evaluate draft angles to ensure the part can be ejected smoothly from the mold.

* **Mold Flow Analysis (CAE):** Software simulates how molten plastic (e.g., ABS, PP) will fill the mold cavity. This helps predict and prevent issues like air traps, weld lines, and uneven filling, which could lead to defects in the final part.

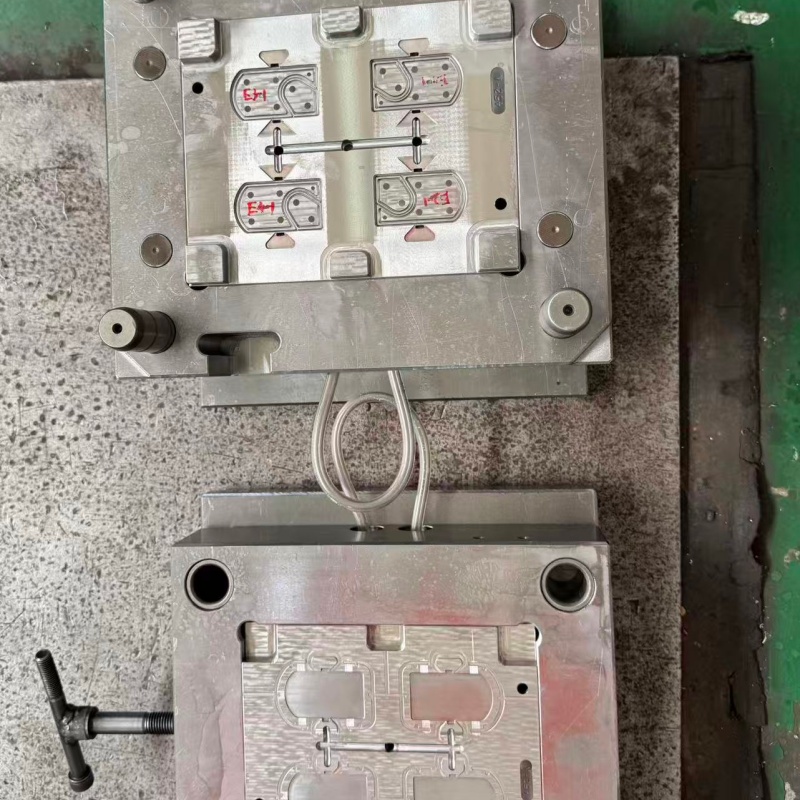

* **Mold Layout Design:** Engineers decide on the type of mold (e.g., two-plate vs. three-plate), the gate location (where plastic enters the cavity), the ejection system (ejector pins, sleeves), and the cooling channel layout. The mold is designed as a multi-cavity tool to produce multiple housings per cycle for efficiency.

2. Material Selection

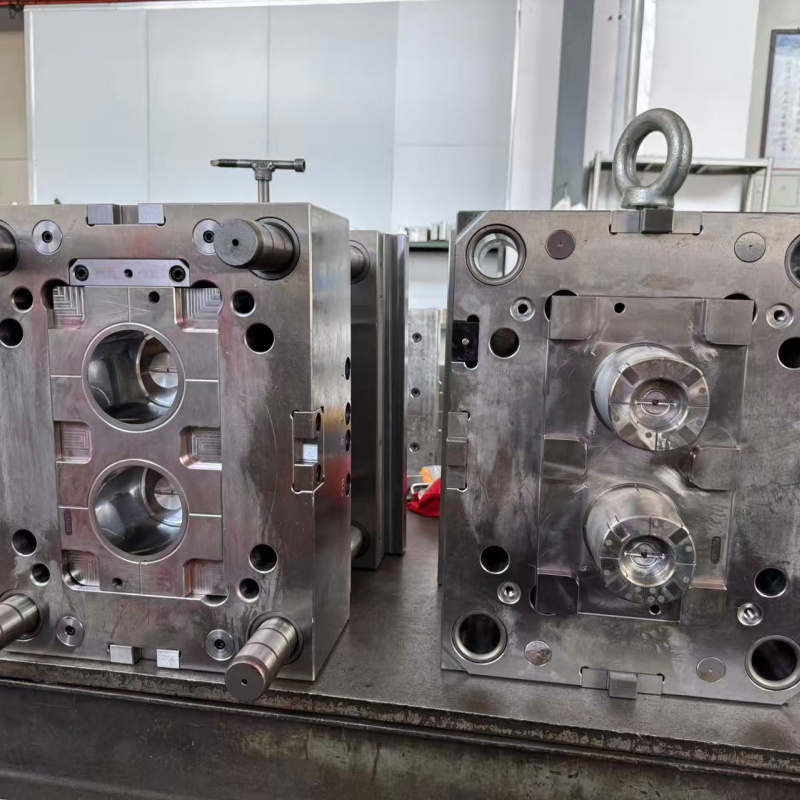

The mold base is typically made from pre-hardened steel (e.g., P20) for its good balance of machinability and durability. However, for the **cavity and core inserts**—the parts that actually form the shape of the housing—high-grade tool steels are used.

* For high-volume production (millions of cycles), hardened steels like **H13** or **Stainless Steel (e.g., S136)** are chosen for their exceptional wear resistance, corrosion resistance (important for glossy finishes), and ability to withstand prolonged pressure and temperature cycles.

3. CNC Machining (Roughing and Finishing)

This is the primary stage of creating the mold. The designed components are manufactured with extreme precision.

* **Rough Machining:** Large blocks of steel are milled to create the general shape of the cavity and core. This process removes the bulk of the material quickly.

* **Semi-Finishing and Finishing:** Using smaller, more precise tools, CNC machines meticulously carve the final geometry, including all subtle curves, button slots, and logos. This stage achieves the required dimensional accuracy and surface texture.

* **Electrical Discharge Machining (EDM):** For intricate features that are difficult for milling tools to reach, such as sharp corners or deep, narrow ribs, EDM is used. An electrode shaped like the desired feature is used to erode the steel shape with sparks, achieving极高的精度.

4. Secondary Operations and Surface Treatment

* **Drilling and Tapping:** Holes are drilled for ejector pins, water lines for cooling, and assembly bolts.

* **Polishing and Texturing:** The surface of the cavity is critically important as it defines the outer surface of the plastic housing. Technicians hand-polish the cavity to a mirror-like finish for a glossy product. Alternatively, if a matte or textured finish (e.g., soft-touch) is required, the cavity is chemically etched or laser-engraved to create that specific texture.

* **Heat Treatment:** The core and cavity inserts may be heat-treated (hardened and tempered) to increase their surface hardness and extend their operational life significantly.

5. Mold Assembly and Fitting

All individually machined components—the cavity inserts, core inserts, ejector plates, guide pins, bushings, and cooling system—are meticulously assembled into the mold base. A master toolmaker ensures that all parts fit together perfectly, with no gaps or misalignments. The movement of the ejector system and the opening/closing of the mold are tested for smooth operation.

6. Trial Shots (Sampling) and Validation

The completed mold is mounted into an injection molding machine for its first test runs, known as **T1 (First Trial)**.

* **Initial Shots:** The machine injects molten plastic into the mold. The initial parts produced are called "shots" or "samples."

* **Dimensional and Visual Inspection:** These first samples are carefully measured using CMM (Coordinate Measuring Machine) and other metrology tools to verify they match the original CAD design. Engineers also check for visual defects like flash, short shots, or sink marks.

* **Fine-Tuning:** Based on the results, the mold and the machine parameters (temperature, pressure, injection speed) are adjusted. This is an iterative process. Sometimes, minor modifications to the mold itself are necessary, a process known as "mold tweaking."

7. Final Approval and Mass Production

Once the samples from the mold are approved by the customer, the mold is cleared for mass production. It is then installed in high-speed injection molding machines where it will reliably produce thousands of identical smart toilet remote control housings throughout its lifespan, with periodic maintenance to ensure consistent quality.

In summary, the making of an injection mold is a sophisticated blend of advanced engineering, precision machining, and skilled craftsmanship, all focused on creating a tool that can mass-produce a high-quality, aesthetically pleasing, and functional product.

.

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.