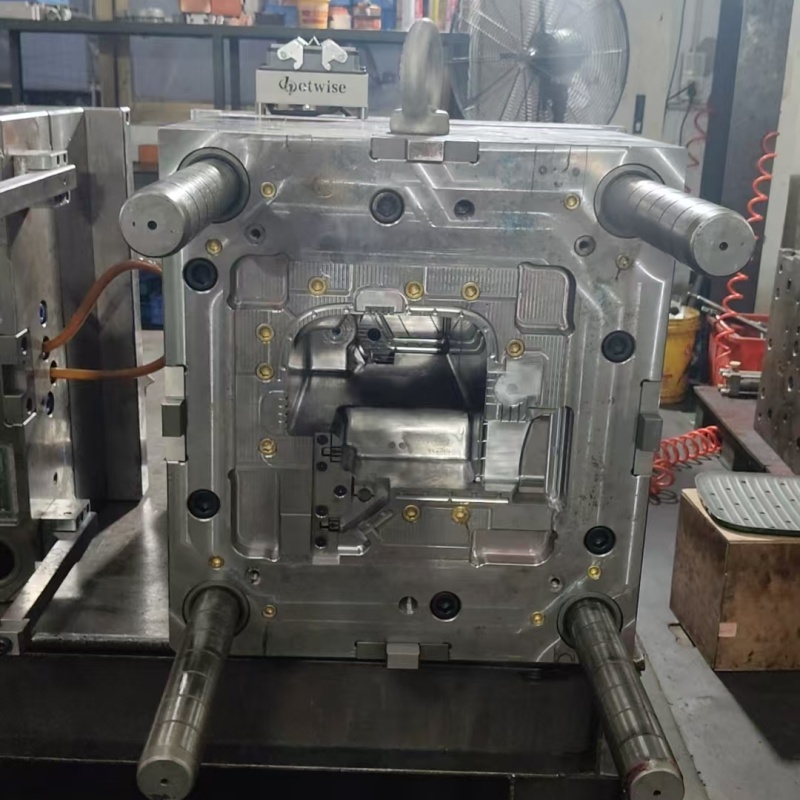

Daily Plastic Cups Injection Mould Custom Thermos Bottle Cap

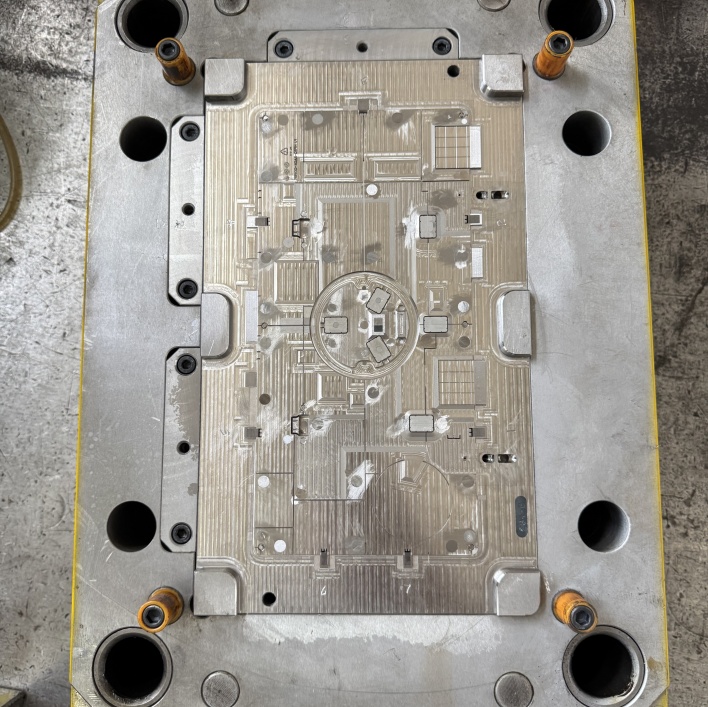

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:4

Delivery Time:45days for mold trail test

Here is a detailed explanation of how plastic cups for thermoses are manufactured, written in English.

How Plastic Lids and Cups for Thermoses Are Manufactured

The plastic cups and lids commonly found on thermoses are typically made through a highly efficient manufacturing process called **Injection Molding**. These parts are usually made from food-grade plastics like **Polypropylene (PP)** or **Tritan™ Copolyester** due to their durability, safety, and resistance to odors and stains.

Here is a step-by-step breakdown of the production process:

1. Design and Mold Creation

The process begins long before any plastic is melted. Engineers design the cup/lid using Computer-Aided Design (CAD) software, meticulously planning its shape, threads (for screwing onto the flask), sealing ridges, and ergonomic features.

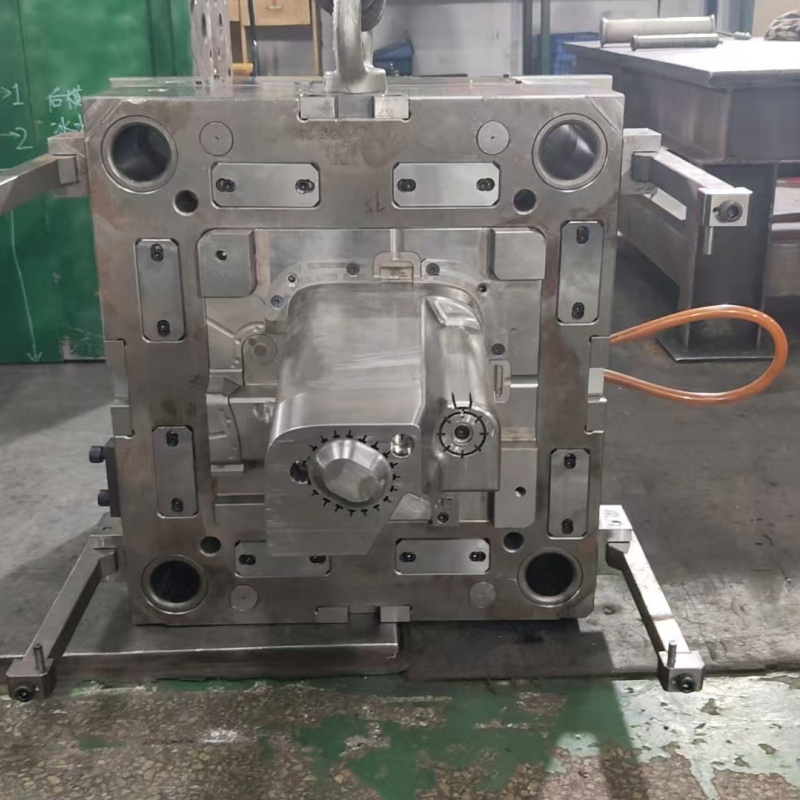

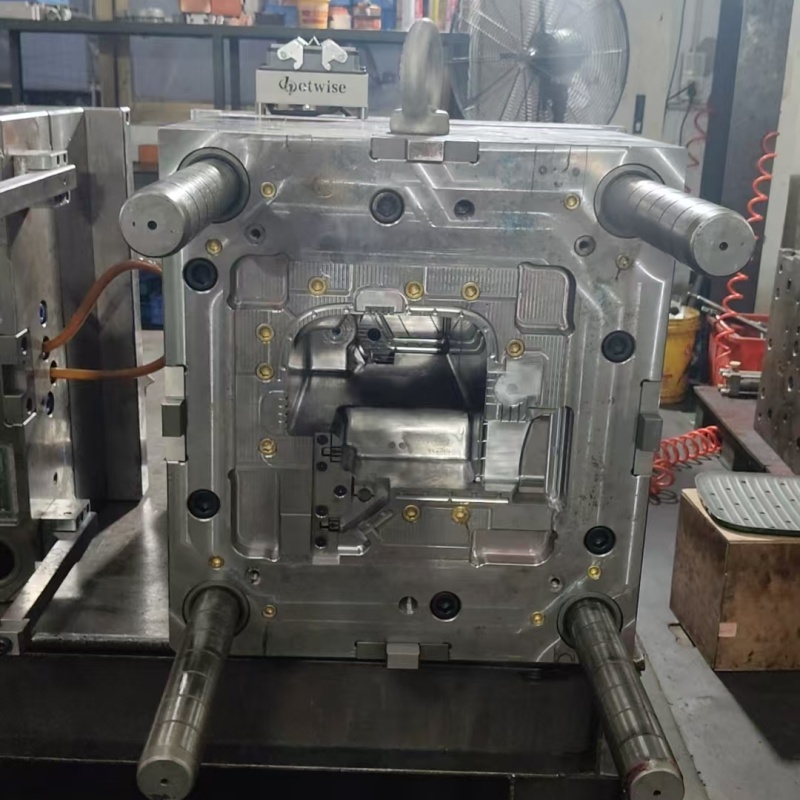

A precision mold, or **tool**, is then machined from hardened steel. This mold is a negative of the final part and is crafted in two or more halves. It contains channels for injecting plastic and complex features to form the threads and seals. The quality of this mold is critical for the final product's accuracy.

2. Material Preparation

The raw plastic is received from the supplier in the form of small pellets or granules. These pellets are often pre-colored with FDA-approved food-safe pigments. For cups designed for hot liquids, materials with high heat resistance (like PP, which can withstand over 100°C) are selected.

The pellets are loaded into a hopper on the injection molding machine, where they are dried (if necessary) to remove any moisture that could cause defects.

3. The Injection Molding Cycle

This is the core of the manufacturing process. The machine performs a continuous, automated cycle:

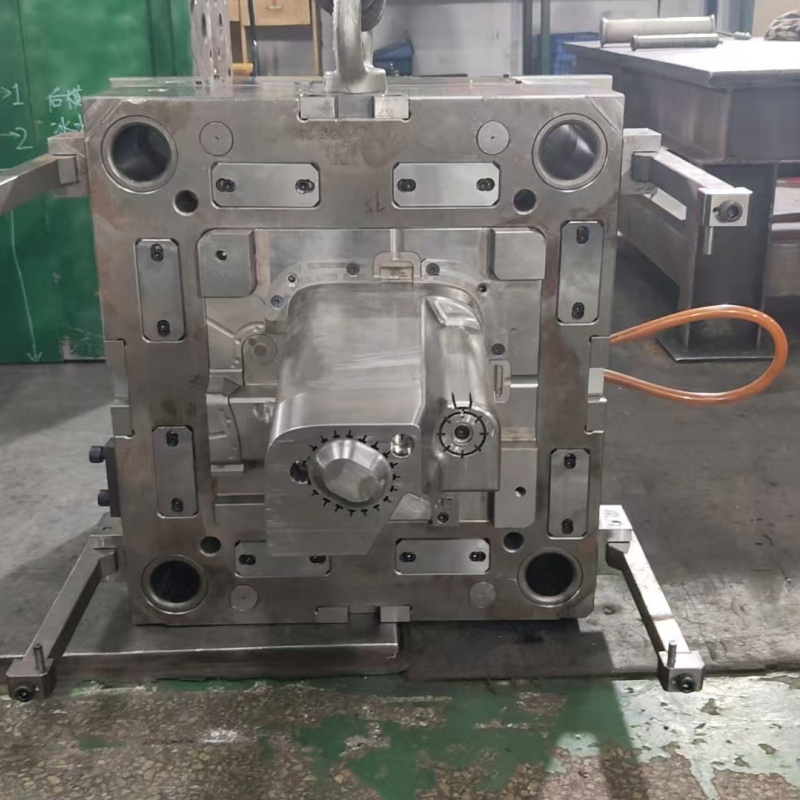

* **Clamping:** The two halves of the steel mold are hydraulically or electrically clamped together with immense pressure (tons of force) to withstand the injection pressure.

* **Injection:** The plastic pellets are fed from the hopper into a heated barrel. A reciprocating screw mixes and pushes the pellets forward. As they travel through the barrel, they are heated to a precise temperature until they become a molten, viscous liquid. This molten plastic is then injected at high pressure into the closed mold cavity through a sprue and runner system.

* **Cooling and Holding:** The molten plastic fills every detail of the mold cavity. Pressure is maintained for a short period ("holding pressure") to pack more material into the mold and prevent shrinkage as the plastic cools and solidifies. Coolant water circulates through channels within the mold to speed up the solidification process.

* **Mold Opening and Ejection:** Once the part is sufficiently cool and solid, the mold halves open. Elector pins, built into the mold, automatically push the finished plastic cup or lid out of the mold cavity. The mold then closes again, and the cycle repeats—often in a matter of seconds.

4. Post-Processing and Finishing

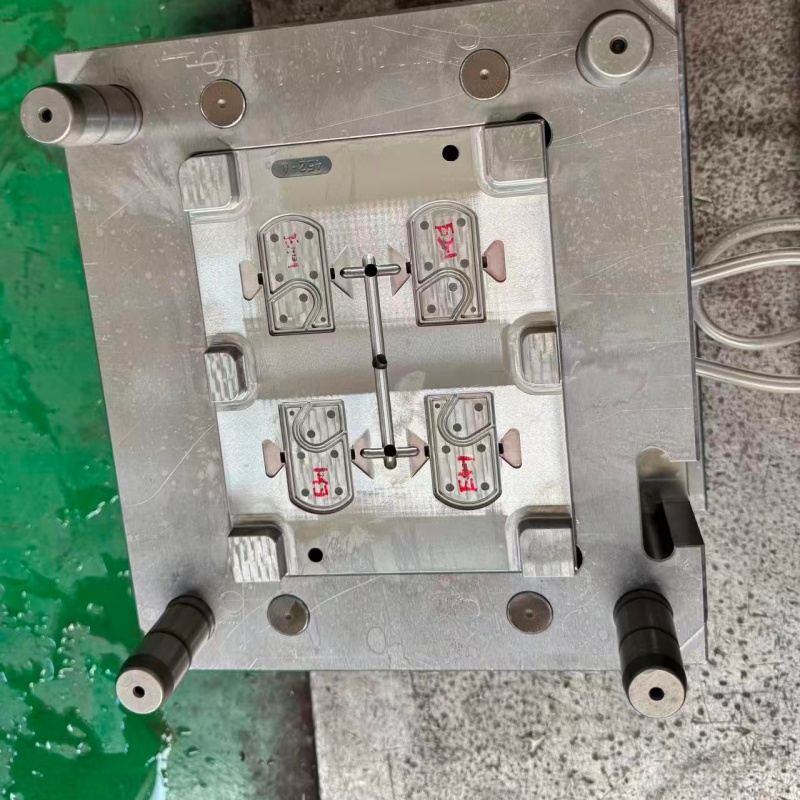

**Degating:** The ejected part will often have small, excess bits of plastic attached—these are the sprue and runner that channeled the plastic into the cavity. These are manually or automatically trimmed off in a process called degating.

**Quality Control (QC):** Parts are rigorously inspected. Checks include:

* **Dimensional Accuracy:** Ensuring threads fit the thermos body perfectly.

* **Visual Inspection:** Looking for flaws like bubbles, discoloration, or incomplete filling.

* **Functionality Testing:** Testing the seal for leak-proof performance.

**Additional Steps:** Some cups may undergo secondary operations, such as:

* **Adding a Silicone Seal:** A separate food-grade silicone gasket is often inserted into a groove in the lid to create the primary leak-proof seal.

* **Printing/Decoration:** Brand logos or measurement markings might be printed on using safe, durable inks.

5. Assembly and Packaging

Finally, the plastic cups and lids are assembled with any other components (like the stainless steel flask body or the silicone gasket), cleaned to remove any dust or particles, and packaged for shipment.

In summary, the creation of a simple thermos cup is a marvel of modern manufacturing, relying on the precision, speed, and repeatability of **injection molding** to produce a safe, reliable, and functional product we use every day.

Product Specification:

Stainless Steel Medical Injection Molding Companies |

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding | 4 | S136 | 45# | 45days | 500000 | 60 |

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.