mold making company ,mold expert in xiamen

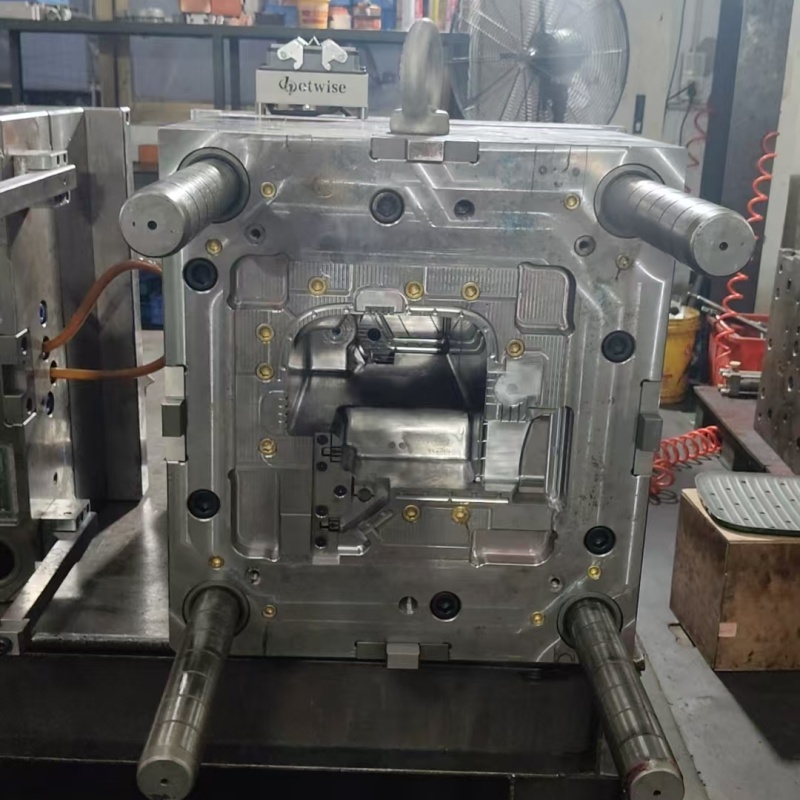

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Delivery Time:45days for mold trail test

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding | 2 | S136 | 45# | 45days | 400000 | 40 |

**A Comprehensive Introduction to Custom Plastic Mold Manufacturing for Electrical Appliance Components**

The modern electrical appliance industry thrives on innovation, functionality, and aesthetic appeal. At the heart of producing the high-quality plastic parts that define today's devices—from coffee makers and air fryers to vacuum robots and smart home systems—lies a critical process: **custom plastic mold manufacturing**. This specialized service is the cornerstone of bringing durable, precise, and cost-effective plastic components to mass production.

**What is Custom Plastic Mold Manufacturing?**

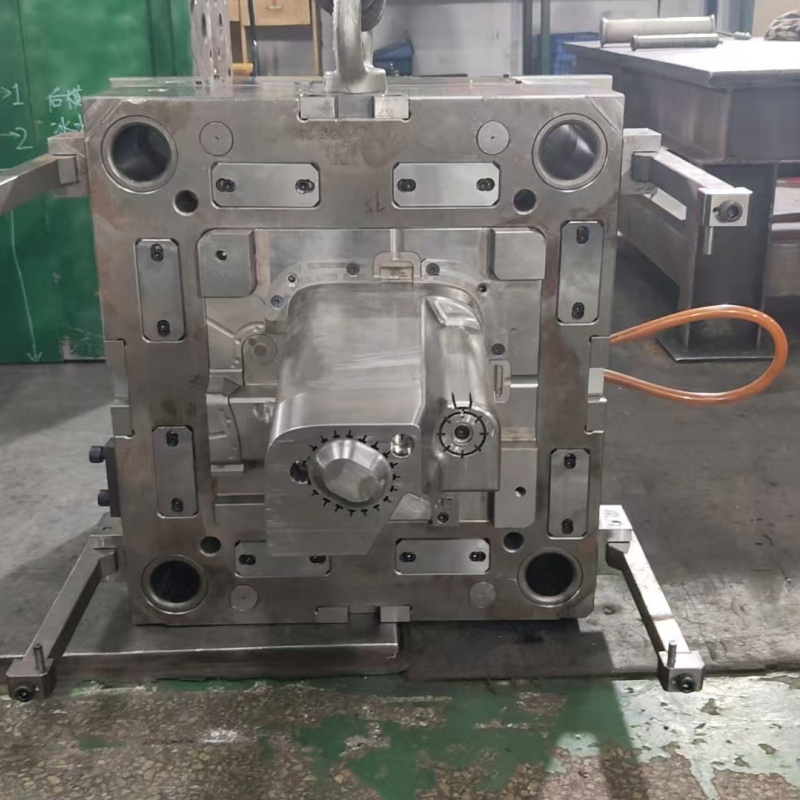

Custom mold manufacturing involves the design, engineering, and fabrication of a unique tool—known as a mold or tool—specifically crafted to produce a particular plastic part. This mold, typically made from hardened steel or aluminum, is injected with molten plastic material under high pressure. Once cooled and solidified, the mold opens to eject a finished plastic component that matches the desired design specifications exactly.

For electrical appliances, this isn't just about creating a shell; it's about producing intricate functional parts like internal brackets, gears, housings, buttons, bezels, and ducting with impeccable precision.

**Key Considerations for Appliance Plastic Parts**

The requirements for plastic parts in electrical appliances are exceptionally high, making the mold-making process crucial. Key factors include:

1. **Precision & Consistency:** Molds must be engineered to produce thousands, or even millions, of identical parts with ultra-tight tolerances. This ensures perfect fit and seamless assembly with other components like PCBs, motors, and metal parts.

2. **Material Selection:** The choice of plastic resin is vital. Appliance parts often require materials with specific properties such as:

* **Heat Resistance:** (e.g., PPE, PPS) for parts near motors or heating elements.

* **High Strength & Durability:** (e.g., Nylon, Polycarbonate) for structural components and housings.

* **Flame Retardancy (UL94 V-0 Rating):** A critical safety standard for most electrical devices.

* **Aesthetic Quality:** Materials that provide a superior surface finish for painting, texturing, or a glossy appearance.

3. **Complex Geometry:** Molds can be designed to create highly complex features—undercuts, living hinges, snap-fits, and internal threads—eliminating the need for multiple parts and secondary operations, thus reducing assembly time and cost.

4. **Durability of the Mold Itself:** The mold must be robust enough to withstand the rigors of high-volume production without losing its precision. Steel molds offer a longer lifespan for massive production runs, while aluminum molds can be a cost-effective solution for prototypes and shorter runs.

**The Custom Mold Manufacturing Process**

The journey from concept to mass-produced part is a collaborative and meticulous process:

1. **Design & DFM (Design for Manufacturability):** Engineers work with the client to optimize the part design for the injection molding process. This stage identifies potential issues, suggests improvements for strength and ease of molding, and ultimately saves time and cost.

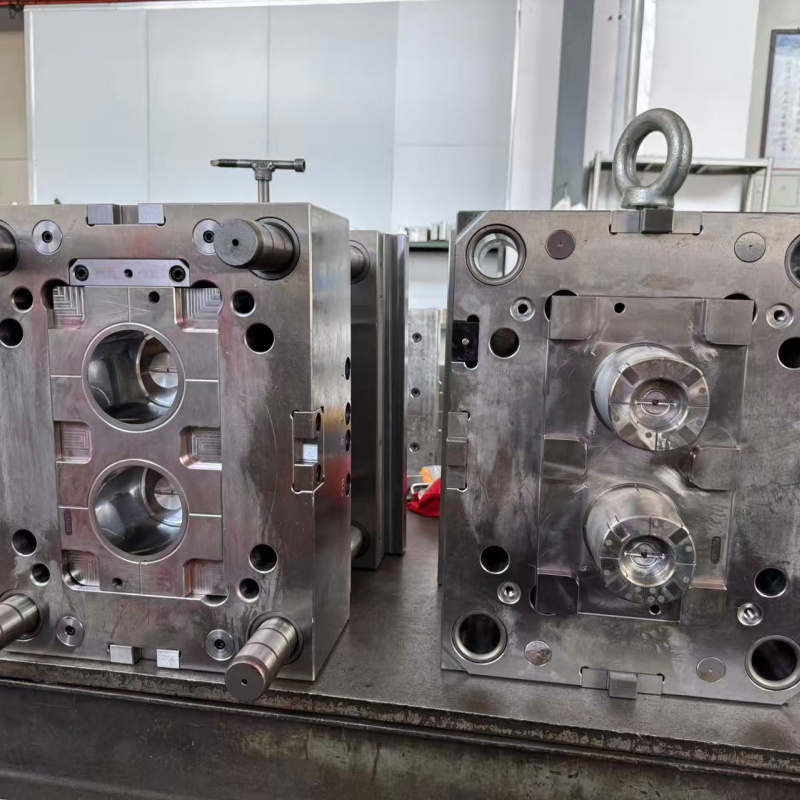

2. **Mold Design:** Using advanced CAD software, mold designers create a detailed 3D model of the mold, defining the core, cavity, ejection system, cooling channels, and gating system.

3. **Precision Machining:** The mold design is translated into a physical tool using state-of-the-art CNC machining, EDM (Electrical Discharge Machining), and other precision techniques.

4. **Assembly & Testing:** The machined components are meticulously assembled by skilled toolmakers. A **Trial Run** is then conducted to produce initial samples. These are rigorously inspected to ensure they meet all quality and dimensional standards.

5. **Production & Maintenance:** Once approved, the mold is installed in an injection molding machine for mass production. Regular maintenance ensures the mold continues to produce high-quality parts throughout its lifecycle.

#### **Why Partner with a Professional Mold Manufacturer?**

* **Expertise:** Deep knowledge of material science, flow dynamics, and thermal management is essential for creating a successful mold.

* **Cost-Effectiveness:** While the initial investment in a custom mold is significant, the per-part cost becomes extremely low in high-volume production, offering excellent long-term value.

* **Speed to Market:** An experienced partner can streamline the entire process, from DFM to production, helping you launch your product faster.

* **Quality Assurance:** A well-made mold is the fundamental guarantee of part quality, consistency, and performance.

.

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.