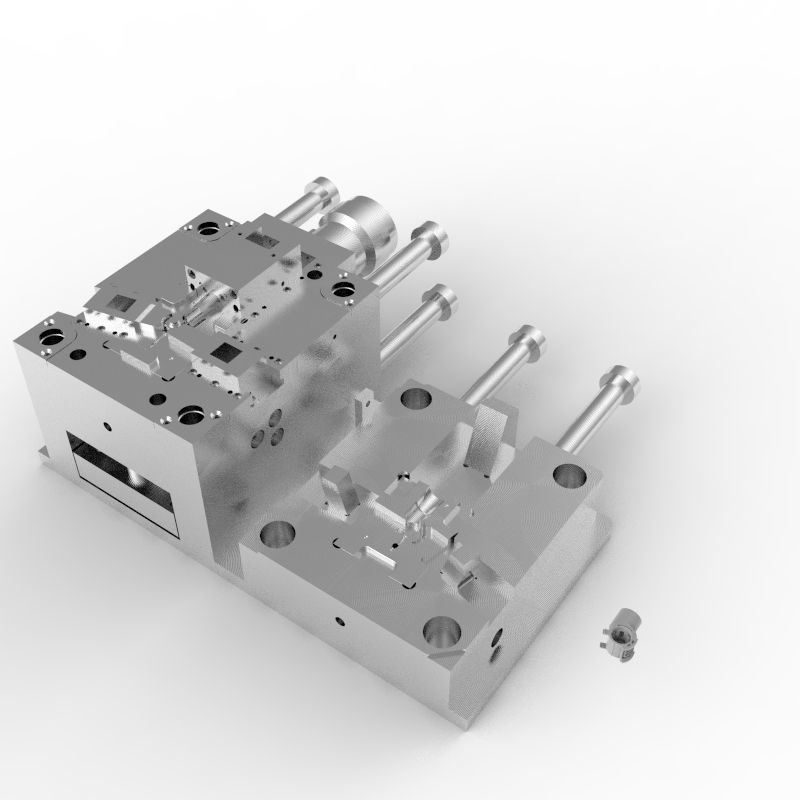

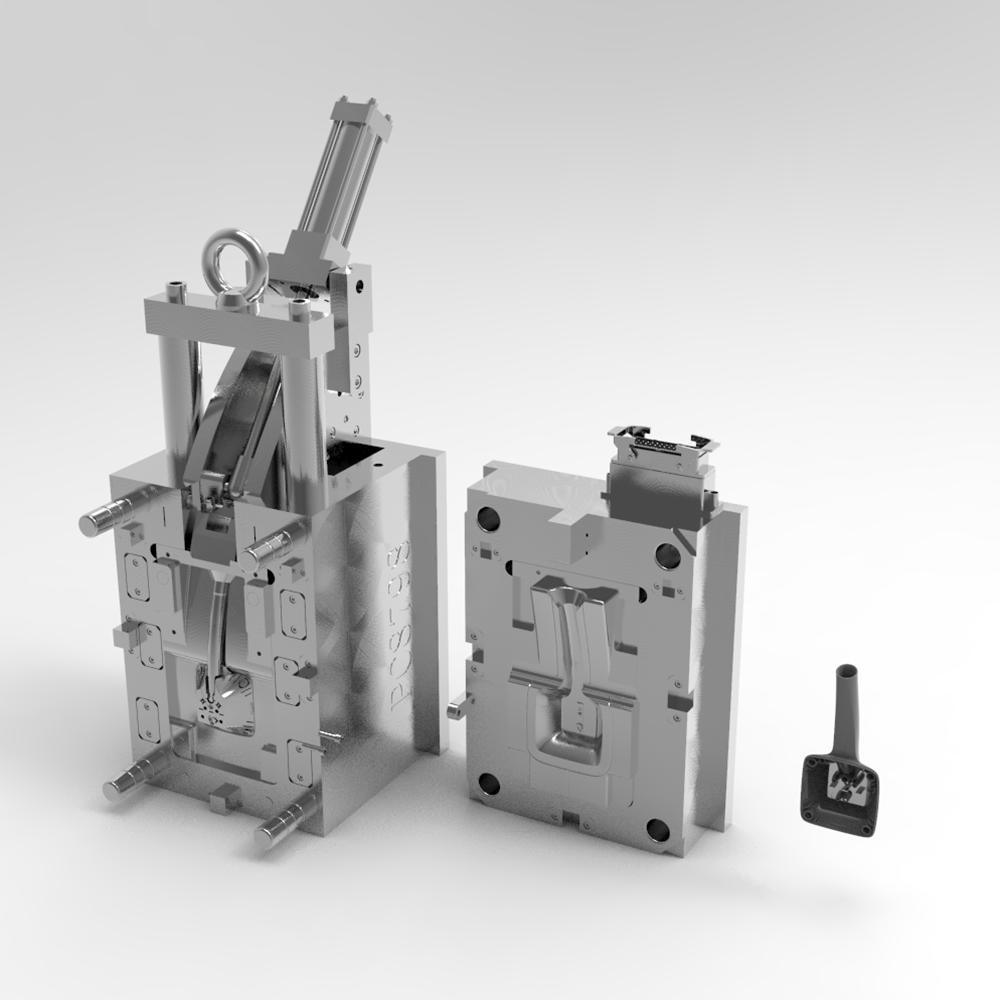

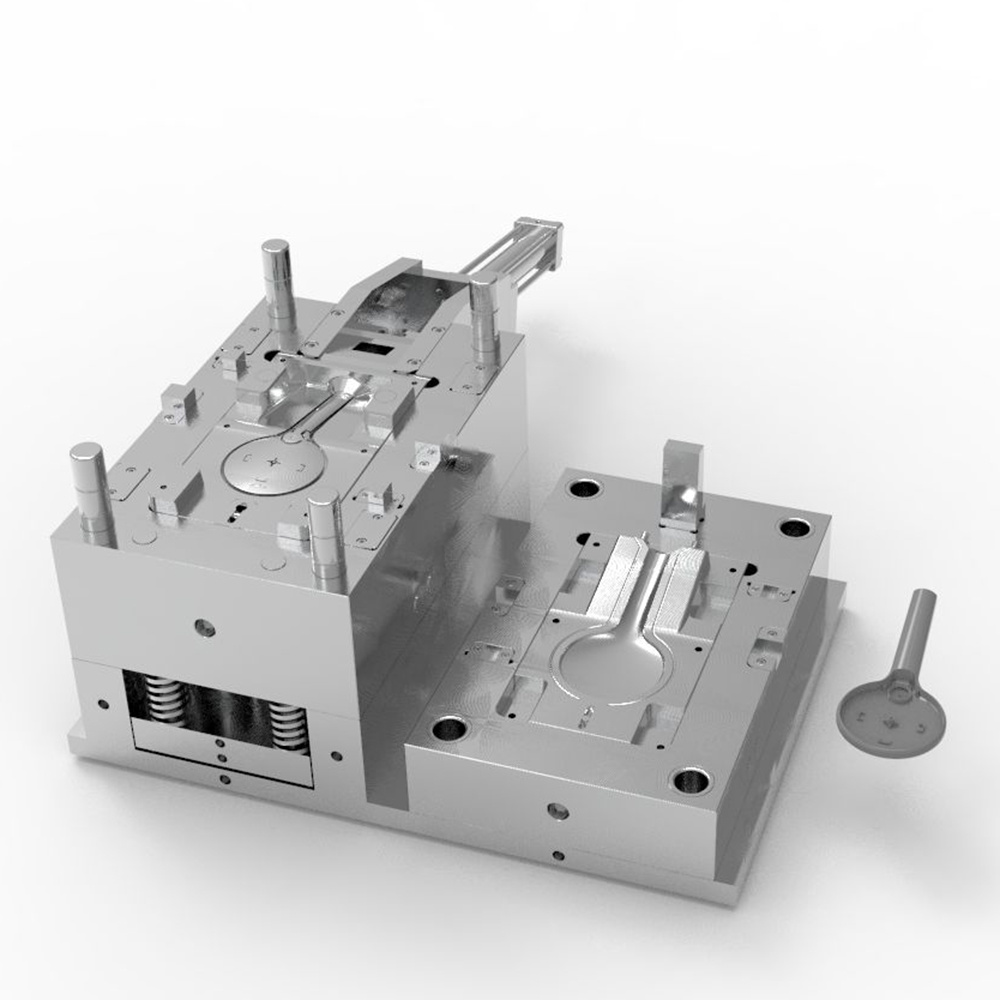

Domestic Appliance Parts Mould Plastic Injection

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

The process of domestic appliance parts mould plastic injection begins with the selection of the right materials and tools. The materials used in the process are typically polypropylene, polyethylene, polystyrene, and polyvinyl chloride. The tools used in the process are typically an injection molding machine and a molding die.Once the materials and tools have been chosen, the next step is to create the mold. This mold must be designed to fit the specific product that is being created. The mold is then filled with the chosen materials and heated to the proper temperature. The injection process then takes place, where the heated material is forced into the mold under high pressure.Once the injection process is complete, the product is removed from the mold and inspected for quality. If the product meets the desired specifications, it is then ready for use

Product Specification:

| Domestic Appliance Parts Mould Plastic Injection | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

plastic injection parts |

2 |

S136 |

45# |

40days |

300000 |

95 |

Domestic appliance parts mould plastic injection is a highly precise process that requires a great deal of skill and knowledge in order to produce a successful product. By utilizing the latest technology and techniques, domestic appliance parts mould plastic injection companies are able to produce products that are both aesthetically pleasing and highly durable

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mould Manufacturing For Hand Shower

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate