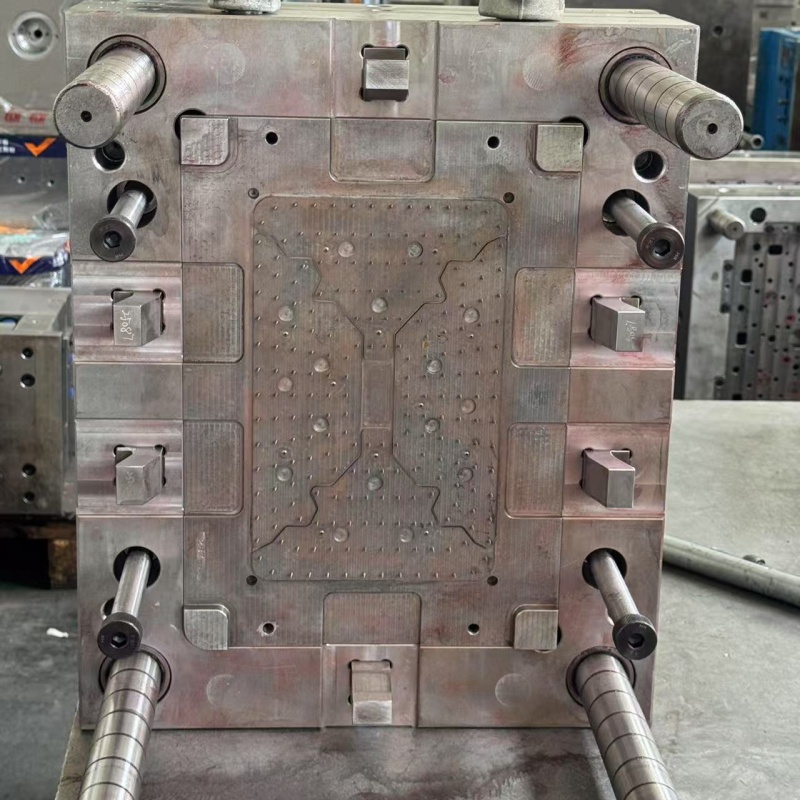

Plastic Moulding Facroty in xiamen city-fengjin mold

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

Delivery time:35 days can send first time samples for customer confirmation

**The Application of Plastic Injection Molds for Bathroom Products in the Building Materials Industry**

The building materials industry has seen significant advancements in manufacturing techniques, with plastic injection molding playing a crucial role in producing high-quality, durable, and cost-effective bathroom products. Injection molds are widely used to manufacture various sanitary ware and bathroom accessories, offering precision, efficiency, and design flexibility.

### **1. Key Bathroom Products Made via Injection Molding**

- **Showerheads ,Top Shower,Rain Shower & Faucets** – Complex internal structures can be precisely molded for optimal water flow.

- **Plastic Toilet Seats & Covers** – Lightweight, hygienic, and resistant to wear and corrosion.

- **Soap Dispensers & Toothbrush Holders** – Customizable designs with smooth finishes.

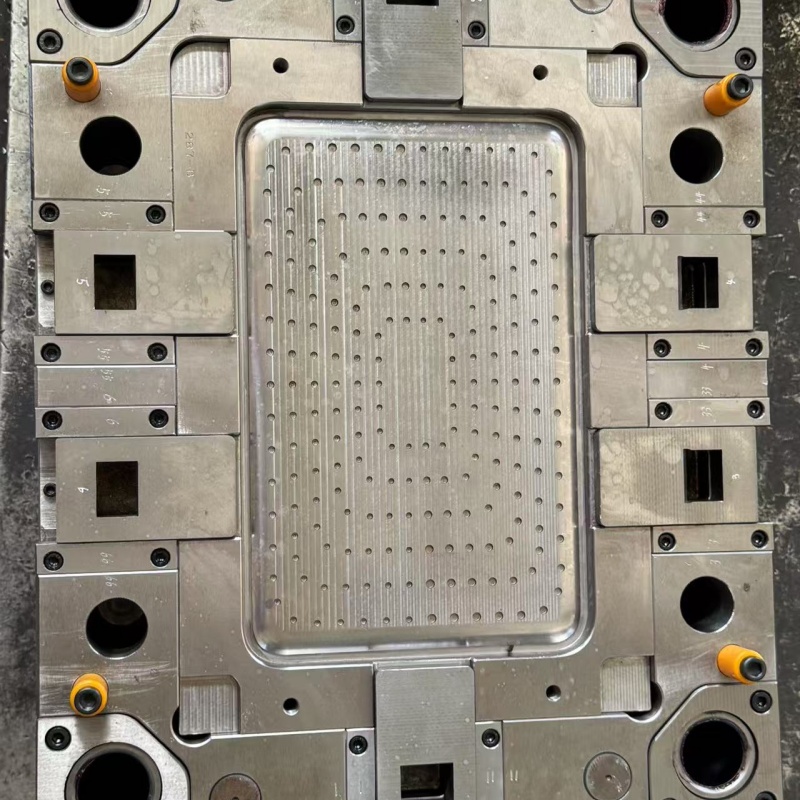

- **Shower Trays & Bathtub Components** – Large, durable parts made using high-pressure molding.

- **Pipe Fittings & Drainage Systems** – Leak-proof and corrosion-resistant plumbing components.

### **2. Advantages of Injection Molding in Bathroom Product Manufacturing**

- **High Precision & Consistency** – Ensures tight tolerances for waterproof and ergonomic designs.

- **Material Efficiency** – Reduces waste compared to traditional machining.

- **Cost-Effectiveness** – Mass production lowers per-unit costs.

- **Design Flexibility** – Allows intricate shapes, textures, and reinforced structures.

- **Durability** – Engineering plastics (PP, ABS, PVC) resist moisture, chemicals, and UV exposure.

### **3. Technological Innovations**

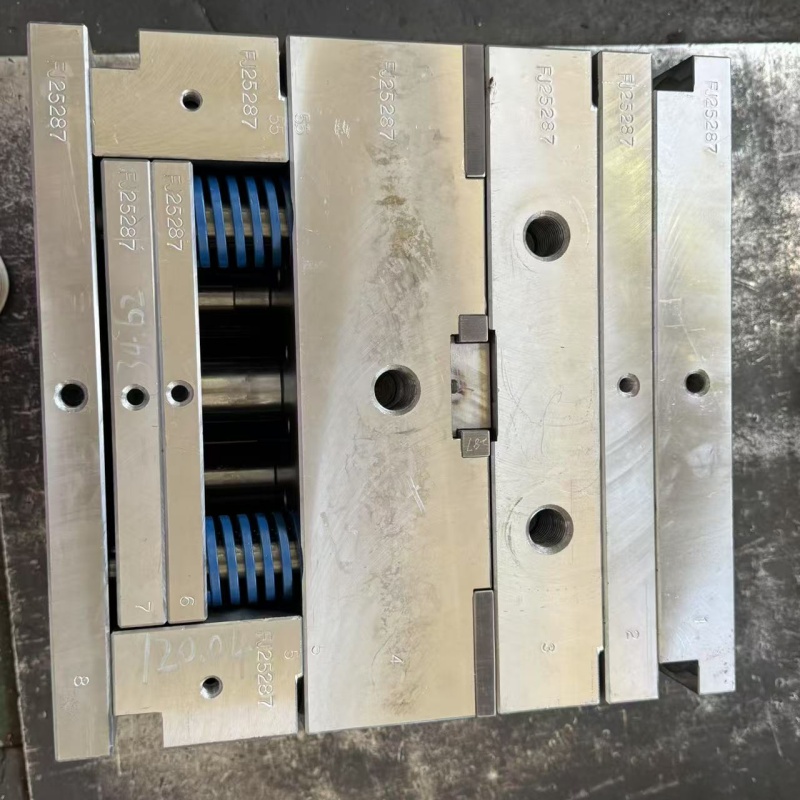

- **Gas-Assisted Injection Molding** – Creates hollow structures for lightweight yet sturdy parts.

- **Overmolding** – Combines soft-touch grips with rigid bases (e.g., non-slip shower handles).

- **Eco-Friendly Materials** – Recycled plastics and bio-resins meet sustainability demands.

### **4. Impact on the Building Materials Sector**

Injection-molded bathroom products align with modern construction trends, offering:

- Faster installation due to lightweight yet durable components.

- Lower maintenance costs with corrosion-resistant materials.

- Customizable aesthetics to match contemporary bathroom designs.

### **Conclusion**

Plastic injection molds have revolutionized the production of bathroom fixtures in the building materials industry, enabling efficient, scalable, and innovative solutions. As technology advances, we can expect even smarter, greener, and more functional designs to emerge, further enhancing bathroom ergonomics and sustainability.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic injection mould | 1 | S136 | 45# | 45days | 200000 | 95 |

We can help to make ultroultrasonic mold for customer as well.

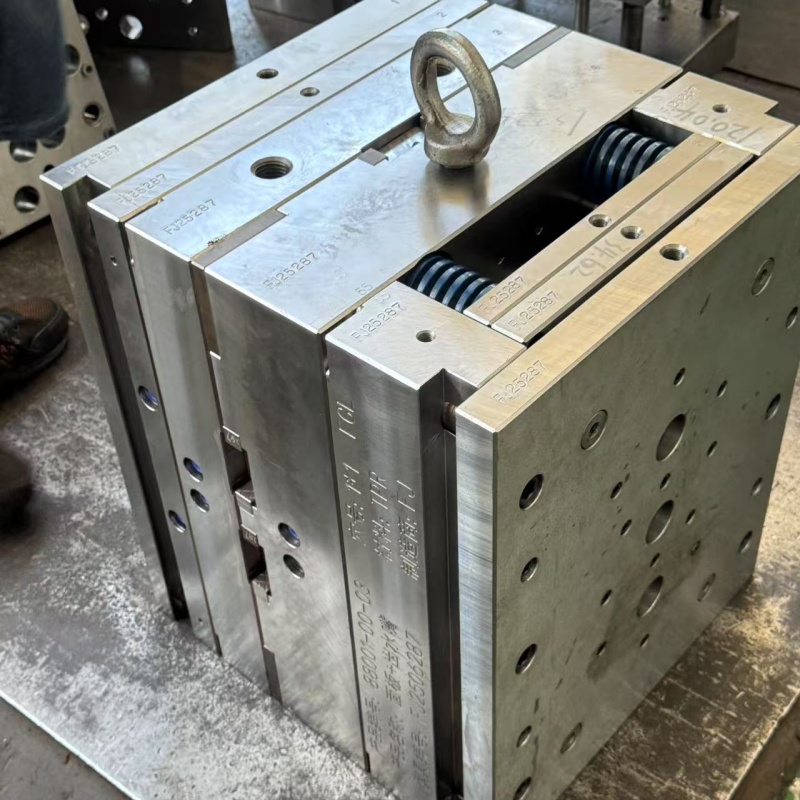

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate