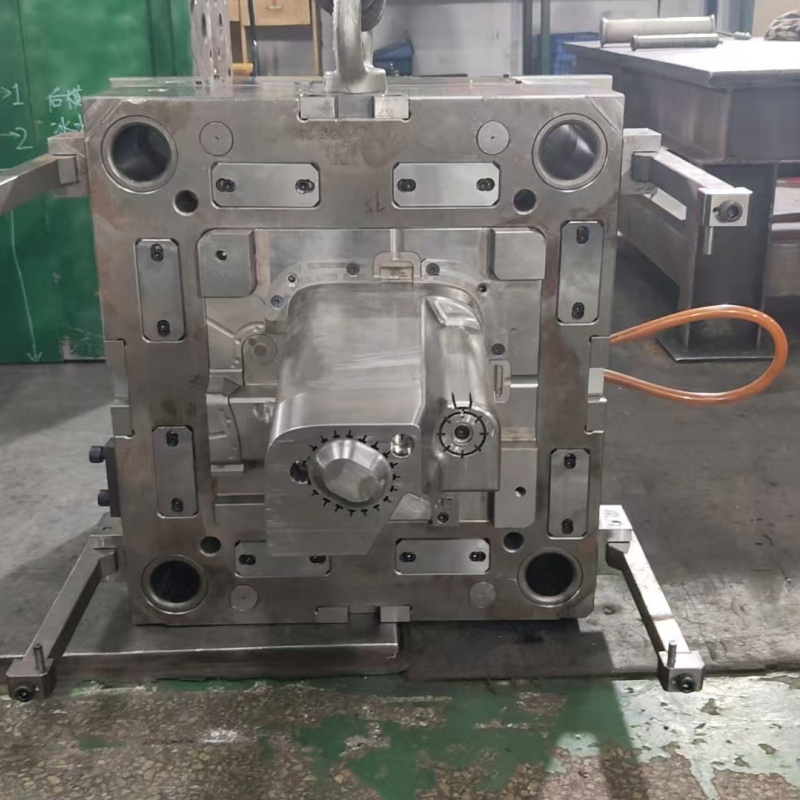

plastic manufacturers in china

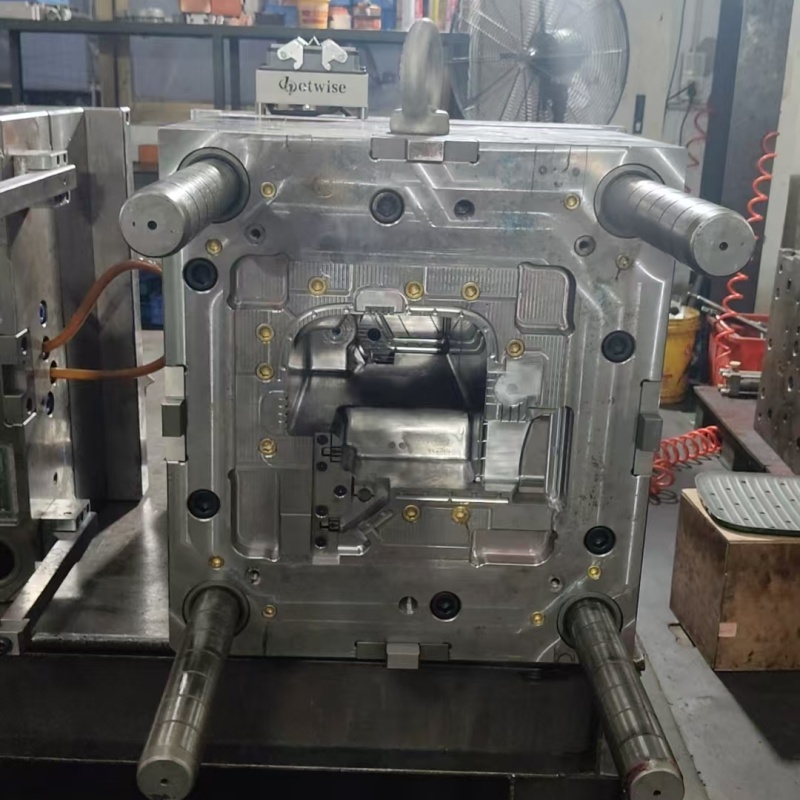

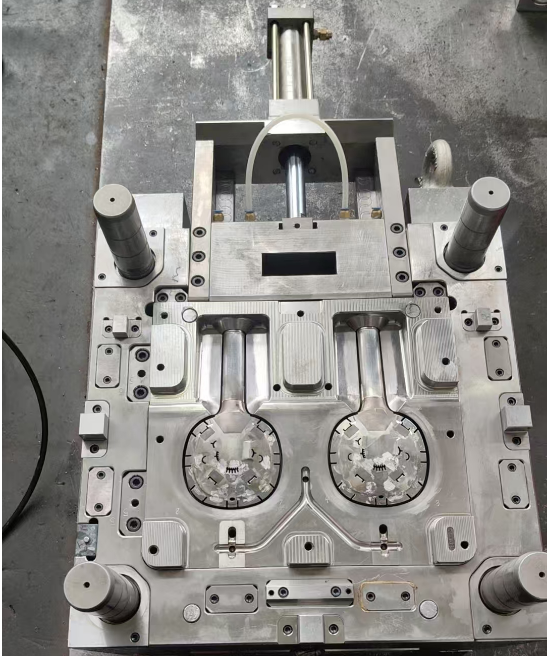

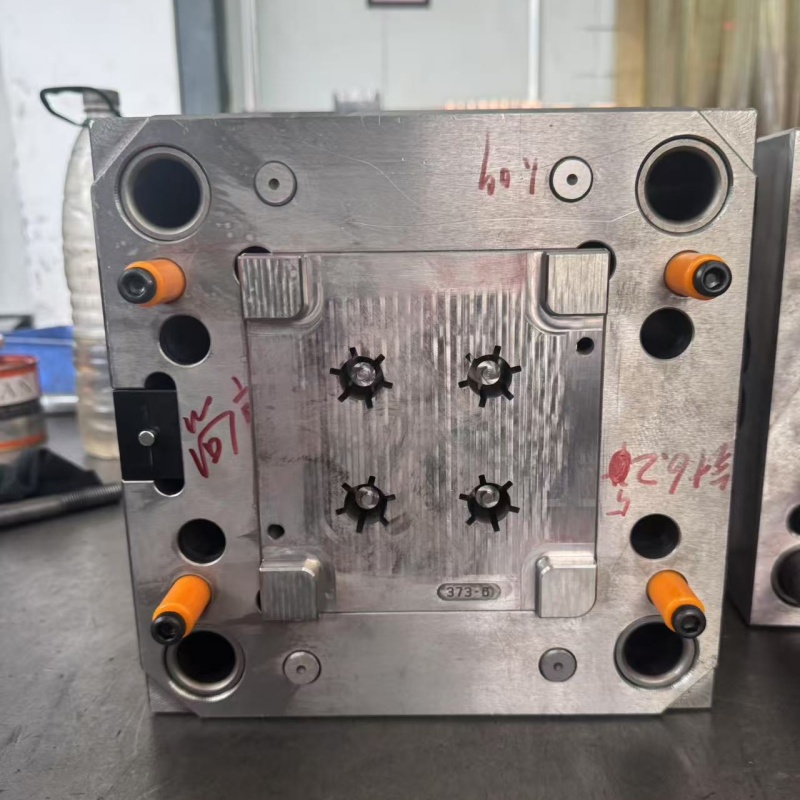

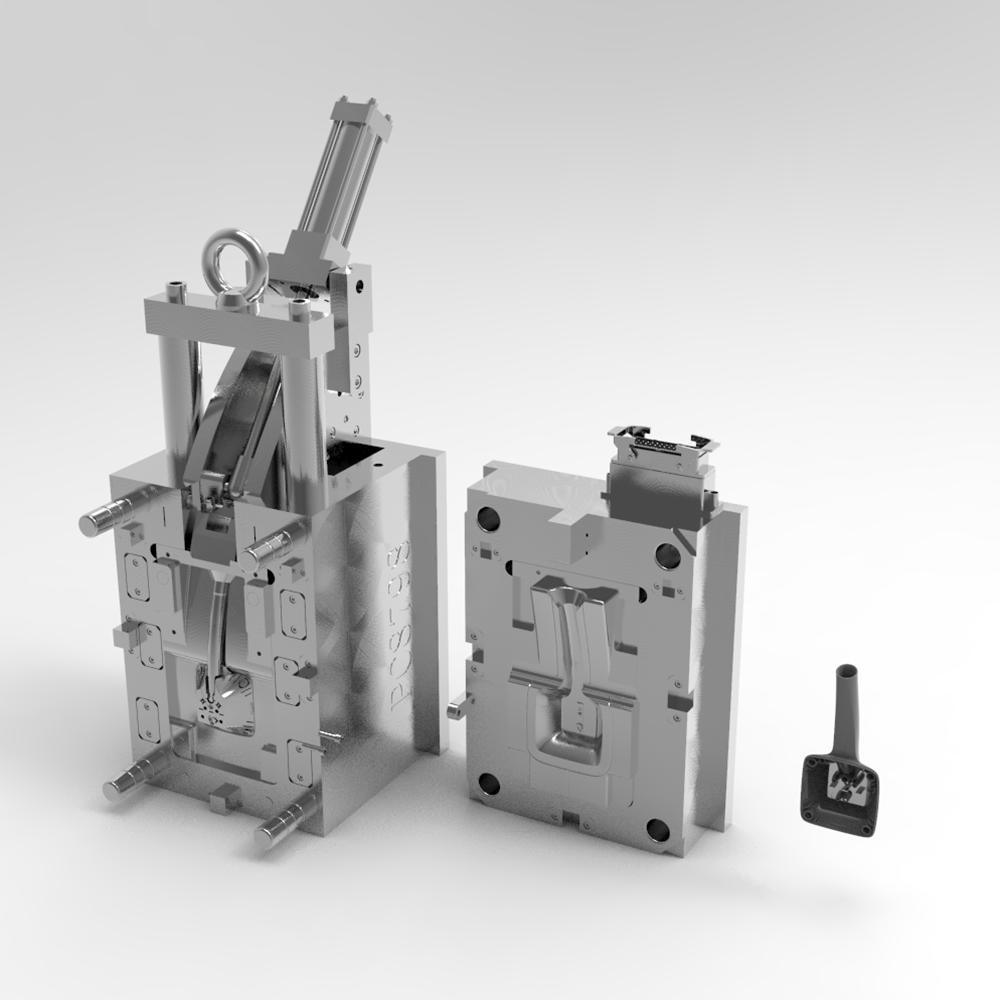

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:8

**The Functional Application of Faucet Aerators in Tap Systems**

Faucet aerators are small yet essential accessories installed at the tip of water taps, designed to enhance functionality, efficiency, and user experience. By mixing air with the water stream, aerators serve multiple practical purposes in both residential and commercial settings.

### **1. Water Conservation**

Aerators significantly reduce water consumption by controlling flow rates without compromising water pressure. Standard faucets without aerators may discharge 8–15 liters per minute (L/min), whereas aerated taps can cut this down to 2–6 L/min. This efficiency aligns with sustainable water management and lowers utility costs.

### **2. Improved Water Pressure & Splash Reduction**

The air infusion creates a smoother, more consistent stream, preventing splashing and ensuring better directional control. This is particularly useful for tasks like handwashing, dish rinsing, or filling narrow containers.

### **3. Cost-Effective Filtration**

Many aerators include mesh screens that trap sediment and debris, protecting plumbing systems from clogs and reducing the need for maintenance. While not a replacement for full-scale water filters, they provide basic particulate filtration.

### **4. Energy Savings (for Hot Water)**

By reducing hot water usage, aerators indirectly decrease energy demands for water heating, contributing to lower electricity or gas bills.

### **5. Versatility & Adaptability**

Aerators come in various flow rates (e.g., 1.5, 2.2, or 4.5 L/min) and thread sizes (standard male/female fittings), making them compatible with most tap designs. Some feature swivel mechanisms for adjustable spray angles.

### **Conclusion**

Faucet aerators are a simple, low-cost upgrade with measurable benefits in water efficiency, user comfort, and system longevity. Their widespread adoption underscores their role in promoting sustainable water use while maintaining practical performance.

*(Word count: ~250)*

**Key Terms**: Water-saving, flow restrictor, laminar flow, sediment filter, sustainable plumbing.

We can offer design service before mold start production.

We have full production line on mold that we can control the mold quality from beginning to end.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding | 8 | S136 | 45# | 45days | 500000 | 60 |

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.