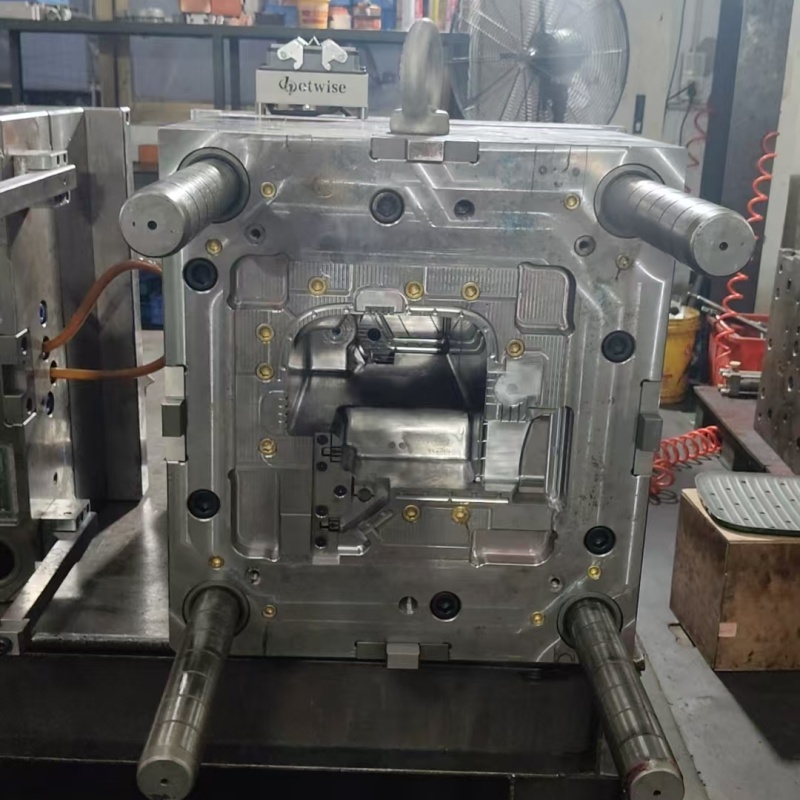

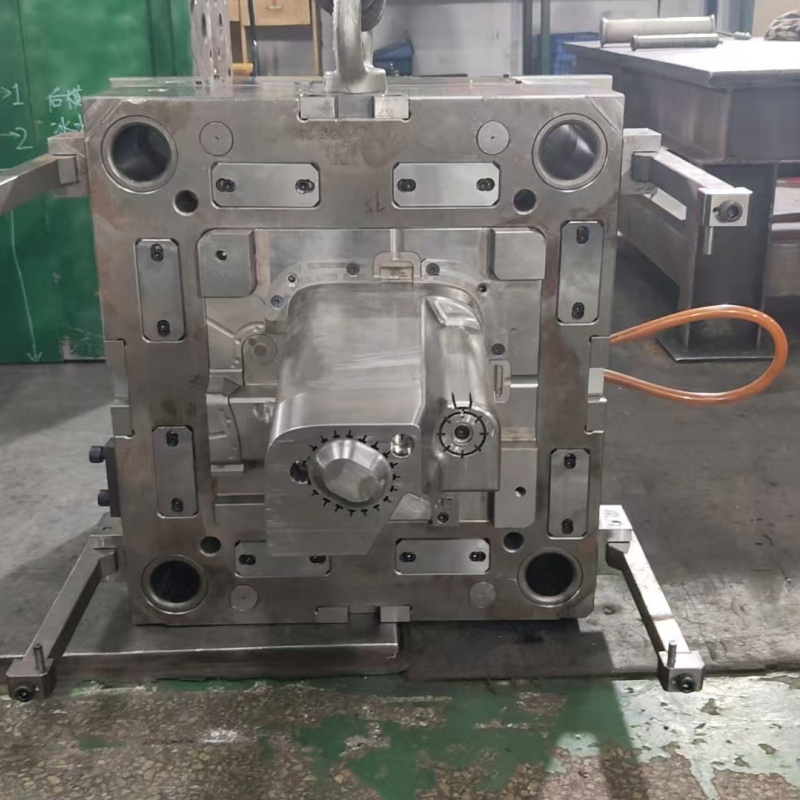

plastic injection in xiamen city,China-Xiamen fengjin mold

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

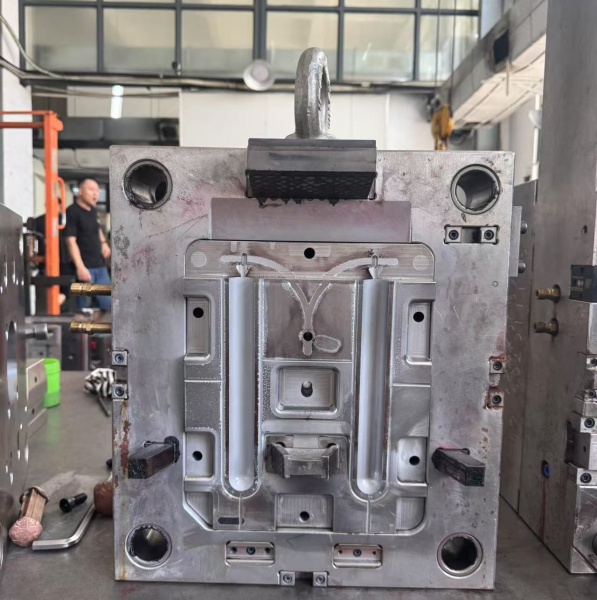

**Injection Molded Handheld Spray Gun: Introduction and Applications**

### **Introduction**

The **injection molded handheld spray gun** is a precision tool widely used in industries requiring controlled liquid or coating application. Its mold is manufactured using high-precision **injection molding technology**, ensuring durability, ergonomic design, and consistent performance. These spray guns are typically made from engineering plastics (such as ABS, PP, or reinforced nylon) combined with metal components for enhanced strength and chemical resistance.

Key features of the injection mold design include:

- **High Precision:** Ensures tight tolerances for smooth operation and leak-proof performance.

- **Ergonomic Shape:** Optimized for user comfort, reducing fatigue during prolonged use.

- **Modular Design:** Allows customization for different nozzles, triggers, and fluid chambers.

- **Cost-Effectiveness:** Mass production via injection molding keeps unit costs low while maintaining quality.

### **Applications**

1. **Industrial Coating & Painting**

- Used in automotive, furniture, and metal fabrication for applying paints, varnishes, or lubricants.

2. **Agriculture & Pest Control**

- Spray guns with chemical-resistant molds are ideal for fertilizers, herbicides, or disinfectants.

3. **Cleaning & Sanitation**

- High-pressure spray guns for car washes, industrial cleaning, or water-based disinfectant spraying.

4. **DIY & Home Maintenance**

- Lightweight, user-friendly models for household painting, gardening, or small repairs.

5. **Medical & Cosmetics**

- Sterilized spray devices for disinfectant application or cosmetic misting (e.g., perfume, skincare).

### **Advantages of Injection Molded Spray Guns**

- **Lightweight yet Durable:** Plastic components reduce weight without compromising strength.

- **Corrosion Resistance:** Suitable for harsh chemicals and humid environments.

- **Scalable Production:** Injection molding supports high-volume manufacturing with uniform quality.

Injection molded handheld spray guns offer a versatile, efficient, and economical solution for fluid dispensing across multiple industries. Advanced mold design enables customization to meet specific pressure, material, and ergonomic requirements, making them indispensable in both professional and consumer markets.

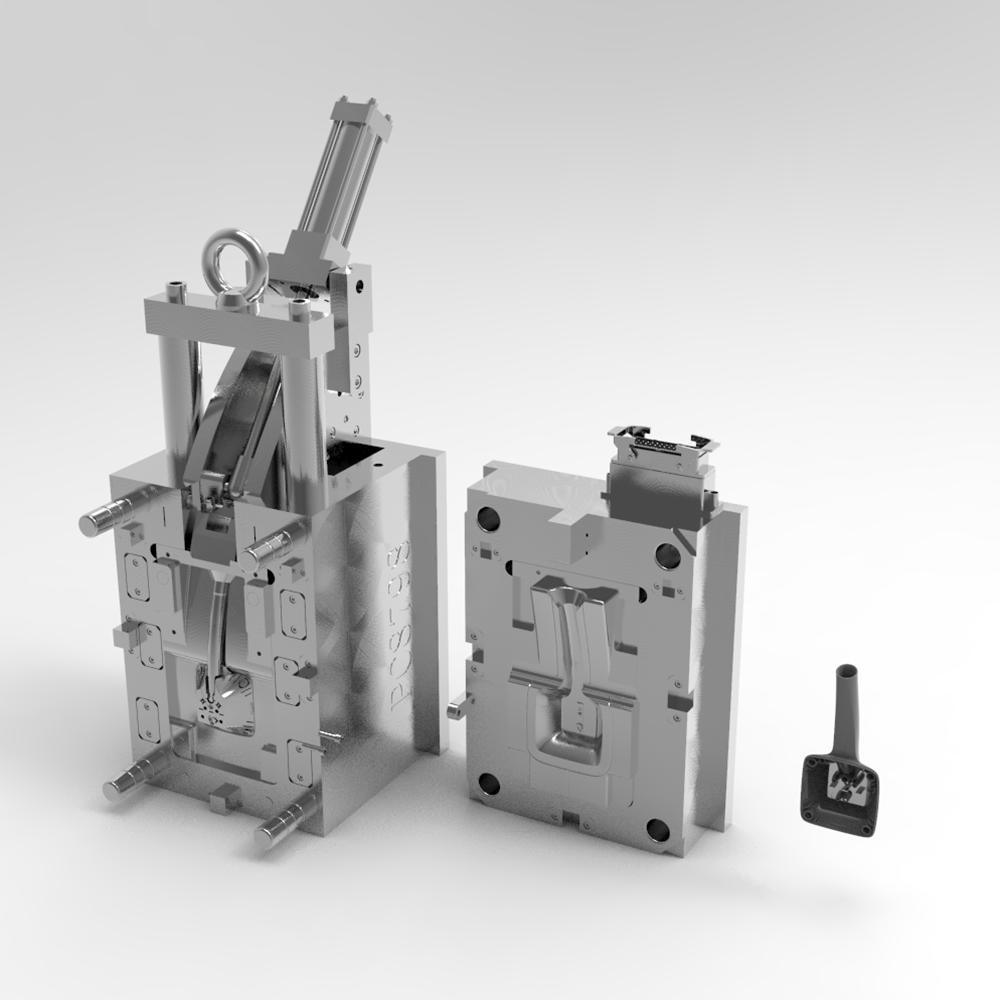

We can offer design service before mold start production.

We have full production line on mold that we can control the mold quality from beginning to end.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

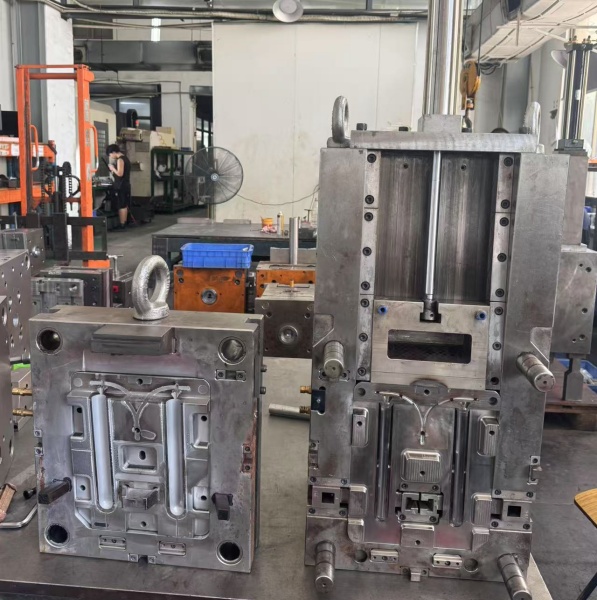

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | injection machine parts | 1 | S136 | 45# | 45days | 400000 | 85 |

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.