Stainless Steel Medical Injection Molding Companies

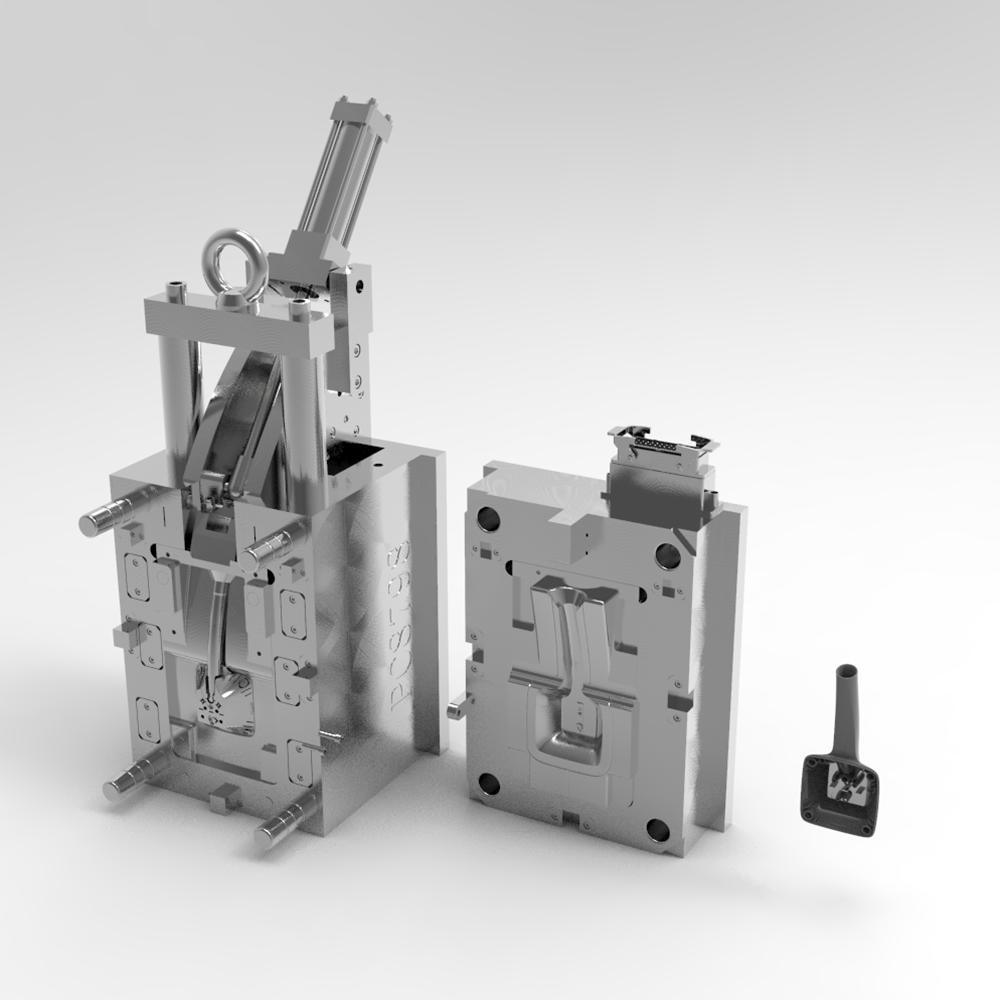

Manufacturing Technique:injection plastic

Mould Core:S136

Mould Base :45# steel

Cavity:24

**The Application of Medical Supplies in the Injection Molding Industry**

The injection molding industry plays a critical role in the manufacturing of high-precision, sterile, and durable medical supplies. With stringent quality standards and growing demand for healthcare products, injection molding has become the preferred method for producing a wide range of medical devices and components.

**Key Applications:**

1. **Disposable Medical Devices** – Syringes, IV connectors, and pipette tips are mass-produced using high-performance plastics like polypropylene (PP) and polyethylene (PE), ensuring cost-effectiveness and safety.

2. **Surgical Instruments** – Components for scalpels, forceps, and housings for handheld devices are manufactured with engineered plastics (e.g., PEEK, PC) for durability and sterilization compatibility.

3. **Implantable Devices** – Certain bio-compatible resins are used to create temporary implants (e.g., orthopedic screws) with precision molding techniques.

4. **Packaging Solutions** – Blister packs, medicine containers, and tamper-proof caps are produced with tamper-evident and child-resistant features.

**Advantages of Injection Molding for Medical Supplies:**

- **High Efficiency** – Enables large-scale production with consistent quality.

- **Material Versatility** – Supports medical-grade polymers (e.g., ABS, PS, TPU) meeting ISO 13485 and FDA requirements.

- **Sterility Assurance** – Cleanroom-compatible processes reduce contamination risks.

- **Complex Geometry** – Allows intricate designs (e.g., microfluidic channels) with tight tolerances.

**Innovation Trends:**

- **Micro-molding** for miniaturized components (e.g., wearable drug delivery parts).

- **Smart Molds** with IoT sensors for real-time quality monitoring.

- **Sustainable Materials** like biodegradable plastics for eco-friendly disposables.

As healthcare demands evolve, the injection molding industry continues to advance, delivering safer, more efficient medical solutions through cutting-edge technology and material science.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | medical injection molding | 1 | S136 | 45# | 45days | 400000 | 95 |

Inaddition we can offer some related products mould like soab case on shower stand and other plastic parts like slidding cover mould,friction pad mould,fasten nut mould,marbles mould,non-slip mat mould,decoration ring moulding,decoration cover of suspension base mold,sprayer body injection mould and so on. The cavity can decide according to customer's production capacity.Some more mould pics we make for your refer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate