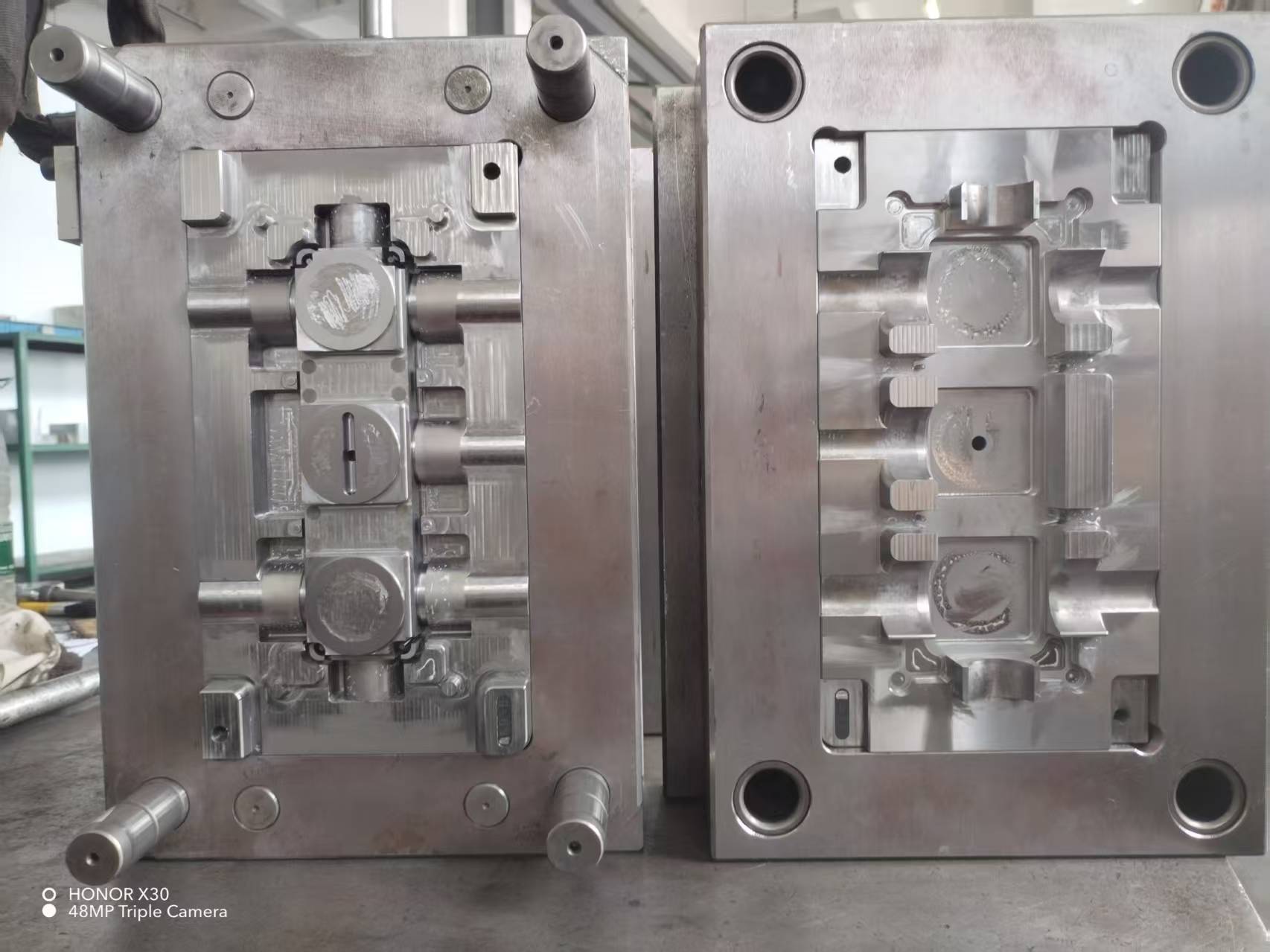

injection mould tool manufacture

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

**Introduction to Injection Molds for Waterway Products**

Injection molding is a highly efficient and precise manufacturing process widely used to produce plastic components for waterway products, such as pipes, valves, fittings, and connectors. These products require durability, leak-proof performance, and resistance to corrosion, making high-quality injection molds essential for their production.

**Key Features of Waterway Product Injection Molds**

1. **High Precision & Durability**

- Molds are typically made from hardened steel or aluminum to withstand high-pressure injection cycles and ensure long-term use.

- Precision machining guarantees tight tolerances, ensuring leak-proof connections in waterway systems.

2. **Complex Geometry Handling**

- Advanced mold designs can produce intricate shapes, including threaded fittings and multi-port connectors, meeting diverse functional requirements.

3. **Corrosion & Wear Resistance**

- Mold surfaces are often treated with coatings (e.g., chrome plating or nitriding) to resist abrasion from plastic melts and corrosive additives.

4. **Efficient Cooling Systems**

- Optimized cooling channels reduce cycle times while maintaining consistent product quality, crucial for mass production.

5. **Customization for Material Compatibility**

- Molds are tailored for thermoplastics like PP, PVC, or PEX, which are common in waterway applications due to their chemical and thermal stability.

**Applications**

Injection molds for waterway products are used in:

- **Plumbing systems** (pipe joints, valves)

- **Irrigation equipment** (sprinkler connectors, drip fittings)

- **Industrial fluid handling** (chemical-resistant tubing components)

**Advantages**

✔ **Cost-effective** for high-volume production

✔ **Consistent quality** with minimal post-processing

✔ **Scalability** for custom designs

By leveraging advanced injection molding technology, manufacturers can produce reliable, high-performance waterway components that meet industry standards for safety and efficiency.

We have full line mold producing equipement in our factory.Every step of mold production we make in our factory.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | pet preform mold design | 2 | S136 | 45# | 45days | 500000 | 65 |

We can help to make ultroultrasonic mold for customer as well.

Other products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

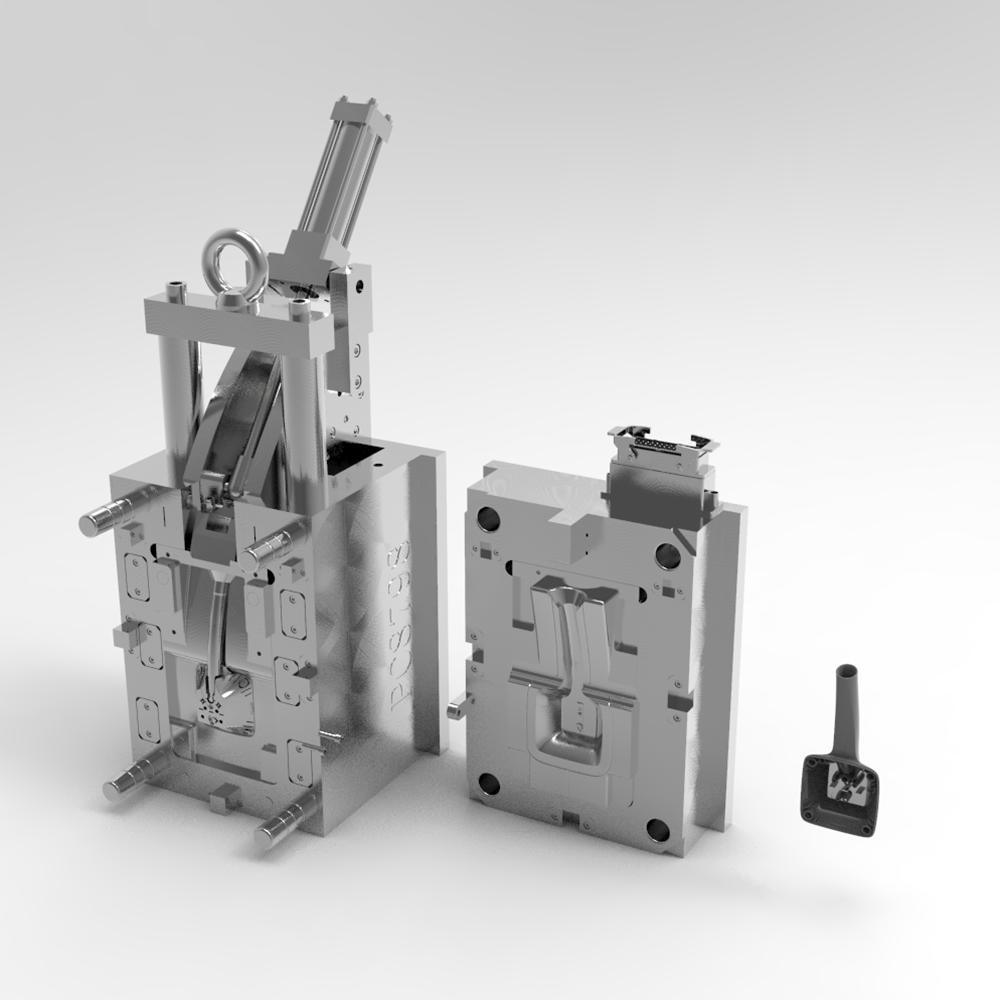

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate