Handshower Ready to sell

Manufacturing Technique:injection

Mould Core:S136H

Mould Base :45# steel

Cavity:2

Delivery time:20days around

this rain shower have 4 different water discharge mode as pic

each piece weight around 262g

Product Specification:

Injection Molding Companies | |||||||

factory | product name | mold cavity | mold core | mold base | mold delivery time | stock | moq(pcs) |

fengjin | shower | 2 | S136 | 45# | 20days | yes | 2000 |

shower sample for refer

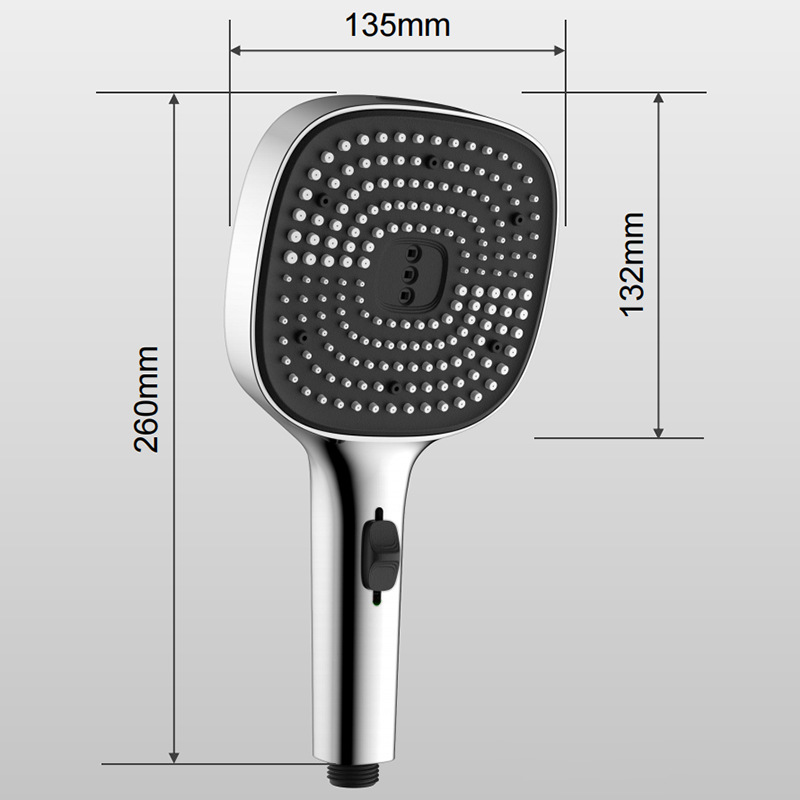

shower details size/specification:

The Full Process of Shower Head: From Mold Manufacturing to Market Sales

The production and marketing of a shower head is a systematic project that integrates precision mold making, injection molding, assembly testing, and global market promotion. The detailed process is as follows:

1. Mold Design & Manufacturing: The Foundation of Product Quality

First, R&D teams design the shower head mold based on product specifications, flow rate requirements, and ergonomic principles, using CAD/CAE software for structural simulation and optimization. For plastic components like the shower head shell and nozzle panel, injection molds are the core—usually made of high-quality S136steel to ensure durability and precision.

The mold manufacturing process includes:

• CNC machining: Carving the mold cavity and core with high-precision CNC milling machines to meet the complex curved surface requirements of the shower head.

• EDM (Electrical Discharge Machining): Processing fine structures such as nozzle holes and thread ports that are difficult to machine with traditional methods.

• Mold polishing: Polishing the cavity surface to a mirror finish, ensuring the smoothness of the injected plastic parts and avoiding burrs.

• Trial molding: Conducting test injections with target materials (ABS, PC, or chrome-plated plastic) to adjust mold parameters, verify dimensional accuracy, and modify any defects.

2. Injection Molding & Component Production

After mold qualification, mass production of plastic components begins in the injection molding workshop:

• Material preparation: Drying raw materials (e.g., ABS resin) to remove moisture and prevent bubbles in the finished products, then adding color masterbatches to achieve the desired surface color.

• Injection molding: Feeding the melted plastic into the mold cavity at high pressure and temperature, holding pressure for shaping, and then cooling and demolding. Key parameters such as injection speed, temperature, and cooling time are strictly controlled to ensure consistent product quality.

• Secondary processing: Performing post-treatments on molded parts, including chrome plating for the shower head surface to enhance corrosion resistance and aesthetics, drilling for additional installation holes, and deflashing to trim excess material.

Metal components (e.g., stainless steel shower hoses, brass mixers) are produced separately through processes like extrusion, stamping, and electroplating.

3. Assembly & Quality Inspection: Ensuring Product Reliability

All components are sent to the assembly line for integration:

1. Assembling the core functional parts: Installing the water distribution valve, nozzle plate, and pressure-regulating device inside the shower head shell.

2. Connecting auxiliary parts: Attaching the handheld shower handle, flexible hose, and wall-mounted bracket.

3. Quality inspection (QC): Conducting multiple tests to meet industry standards:

◦ Water pressure test: Checking for leaks under 0.8–1.0 MPa pressure to ensure sealing performance.

◦ Spray mode test: Verifying that all spray modes (rain, massage, mist) switch smoothly and deliver uniform water flow.

◦ Durability test: Simulating 50,000+ times of switch operation and hose bending to confirm service life.

◦ Material safety test: Detecting heavy metals and harmful substances to comply with international standards (e.g., FDA, CE).

4. Packaging & Branding: Enhancing Product Competitiveness

Qualified shower heads enter the packaging stage, which focuses on protection and brand presentation:

• Inner packaging: Using shock-absorbing materials (e.g., EPE foam) to fix the product and prevent damage during transportation; attaching user manuals in multiple languages (English, Spanish, German) for global sales.

• Outer packaging: Printing brand logos, product features and barcodes on cartons. Premium products may adopt gift box packaging to target high-end markets.

5. Market Sales & Distribution: Reaching End Consumers

The final step is to deliver the product to consumers through diversified sales channels:

• After-Sales Service: Providing warranty services, replacement parts, and online technical support to improve customer satisfaction and build brand loyalty.

Xiamen fengjin mold industry main to offer moulds and parts for customer,we have some ready products to sell as well.Welcome to contact us details for what you need.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Packing can be customized if qty over 3000pcs.

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom.

Let's work for you on 2026.