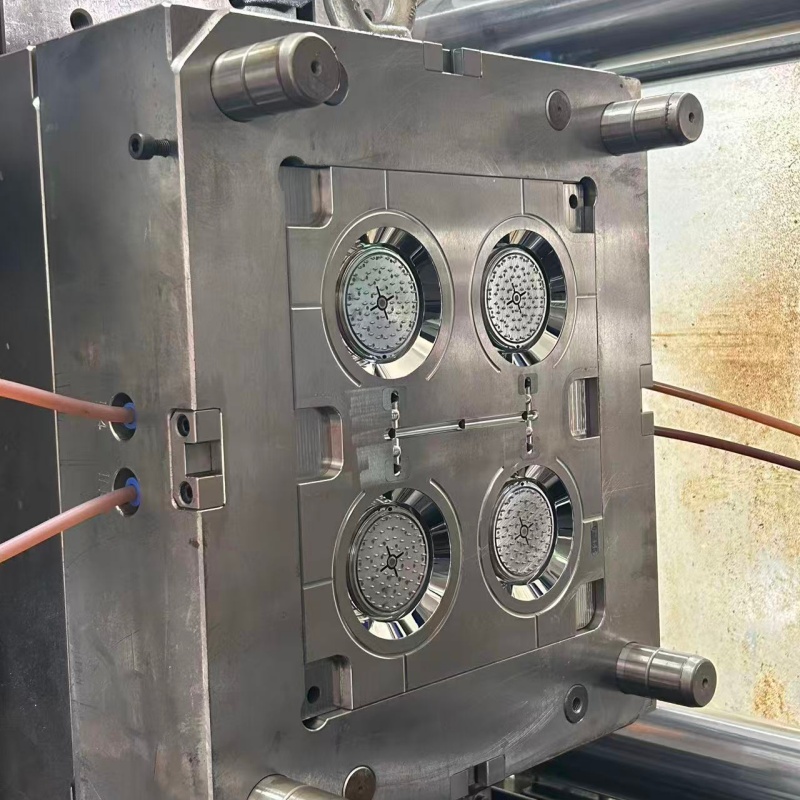

Round Wall Rain Shower Make By Xiamen Fengjin Injection Manufacturer

Manufacturing Technique:plastic injection molding process

Mould Core:S136

Mould Base :45# steel

Cavity:4

Delivery Time:60days for mold trail test

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | china mold maker | 4 | S136 | 45# | 45days | 400000 | 40 |

Below is the Introduction to Wall Rain Shower Molds

Wall rain shower molds are core manufacturing tools designed specifically for producing high-precision, consistent wall-mounted rain shower products. As the foundation of shower fixture production, these molds play a decisive role in determining the quality, performance, and aesthetic appeal of the final products, widely serving bathroom hardware manufacturers, building materials suppliers, and custom卫浴 brands.

Core Design Features

The design of wall rain shower molds is tailored to the functional and structural requirements of rain showers. Firstly, precision engineering is a key highlight—molds are crafted with micron-level accuracy to ensure the smoothness of water outlet holes, the tightness of connection interfaces, and the uniformity of the shower surface. This precision prevents water leakage, guarantees stable water flow, and enhances user experience. Secondly, structural optimization is implemented based on product types: for round, square, or irregularly shaped rain showers, molds adopt split-type or integrated structures, with detachable components for easy maintenance and mold release. Additionally, flow channel simulation is integrated into the design phase; through fluid dynamics analysis, mold flow channels are optimized to ensure uniform water distribution from each outlet hole, achieving the signature "rain-like" spraying effect.

High-Quality Material Selection

Material selection directly impacts the durability and production efficiency of wall rain shower molds. Most high-performance molds are made of pre-hardened steel or stainless steel: pre-hardened steel offers excellent wear resistance and toughness, reducing deformation during long-term high-pressure injection molding; stainless steel boasts superior corrosion resistance, adapting to the humid working environment of mold processing and extending the mold’s service life. For high-gloss or textured shower surfaces, mold cavities are treated with polishing, sandblasting, or etching techniques to replicate fine surface details, meeting diverse aesthetic demands of end-users.

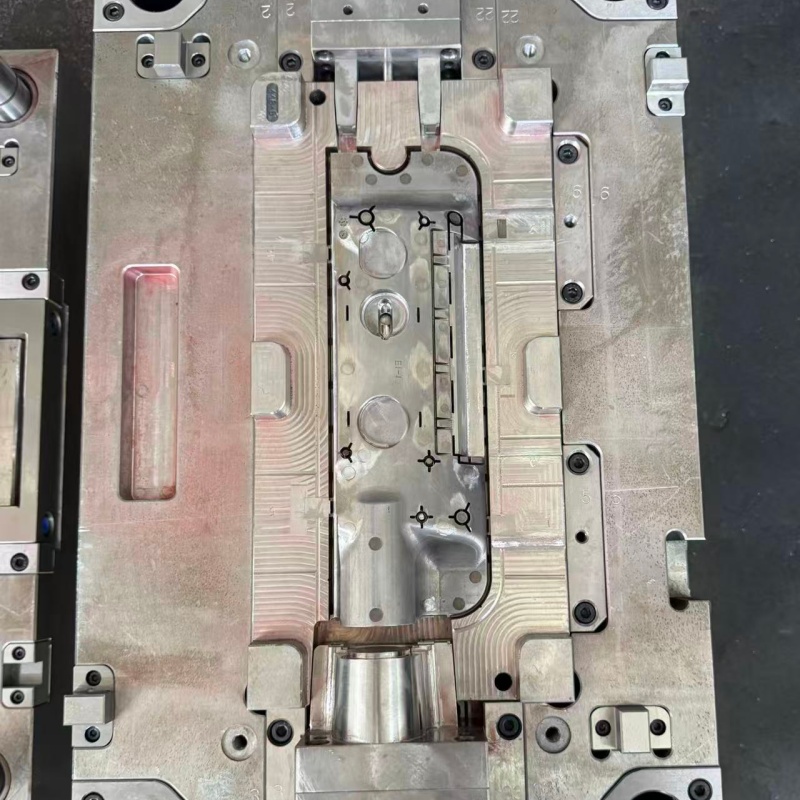

Advanced Manufacturing Processes

The production of wall rain shower molds relies on cutting-edge manufacturing technologies. CNC machining centers are used for high-precision milling and drilling, ensuring the accuracy of mold components. EDM (Electrical Discharge Machining) is employed for processing complex cavities and narrow slots that are difficult to reach with traditional tools, achieving intricate structural designs. After machining, molds undergo strict quality inspections, including coordinate measuring machine (CMM) testing and trial molding, to verify dimensional accuracy and product assembly performance. These processes collectively ensure that each mold can stably produce qualified products in mass production.

Application Advantages and Customization Capabilities

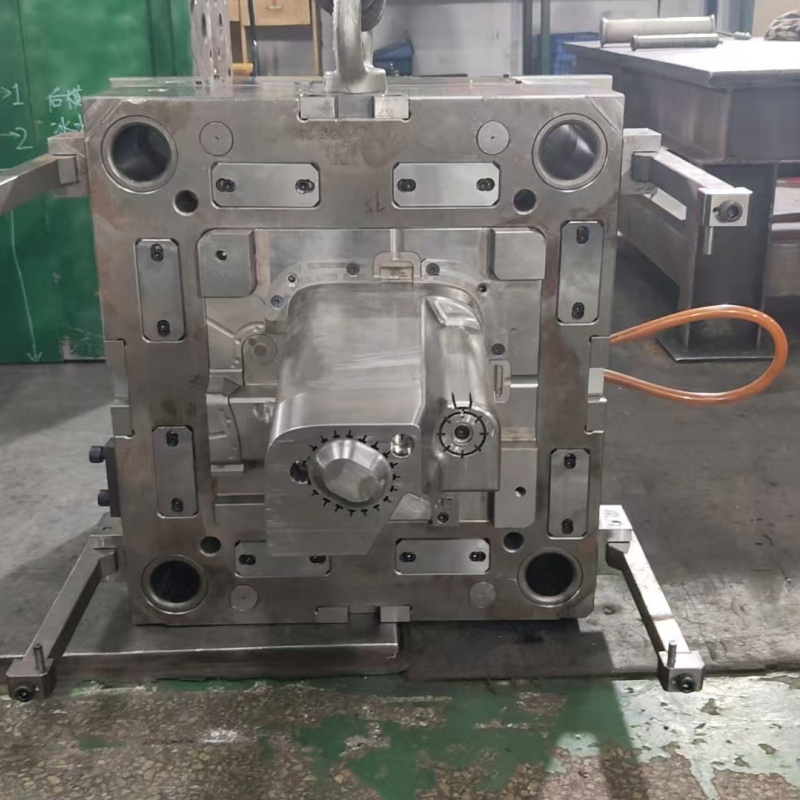

Wall rain shower molds excel in mass production scenarios, enabling efficient, standardized manufacturing that significantly reduces production costs and shortens delivery cycles for enterprises. Moreover, they offer strong customization capabilities: manufacturers can adjust mold designs according to customer requirements, such as modifying shower sizes, outlet hole patterns, or connection port specifications, to develop personalized products. In response to the trend of smart bathrooms, molds can also be customized to accommodate built-in sensors or water-saving components, supporting the production of high-value-added rain shower products.

In the competitive bathroom hardware market, high-quality wall rain shower molds are essential for enterprises to improve product competitiveness. With continuous innovations in design concepts and manufacturing technologies, these molds will continue to adapt to the evolving demands of energy conservation, intelligence, and personalization, driving the development of the wall rain shower industry.

.

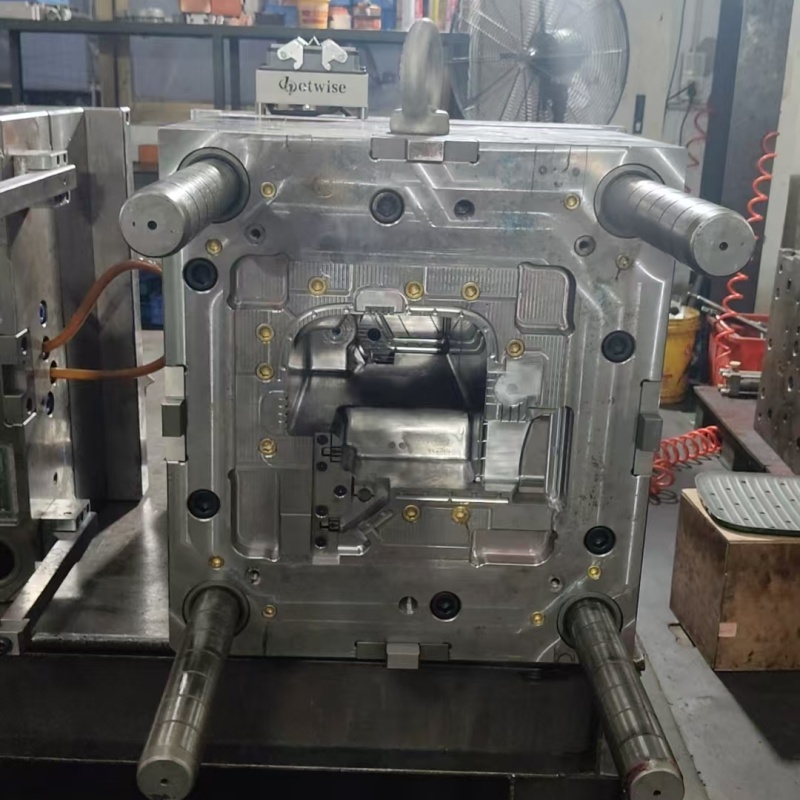

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.