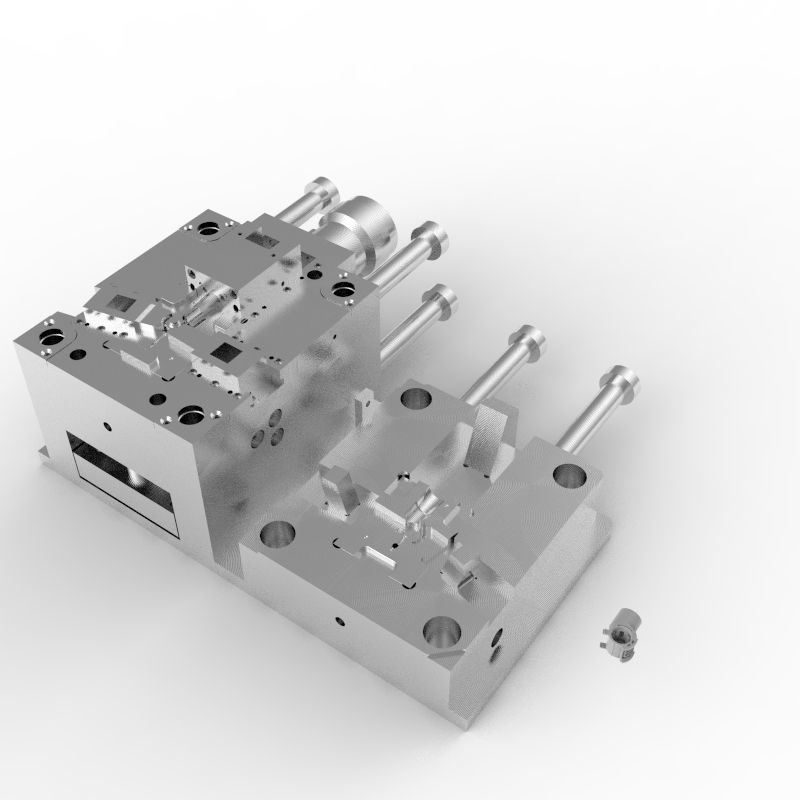

Plastic Injection Mould For Rectangle Shower In Bathroom

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

This hand shower body mould have one cavity, 300000 shots require by customer on working life.It will take around 35 -40days to delivery. Normally 5-7 day for 3D,after customer confirm will start mold production.

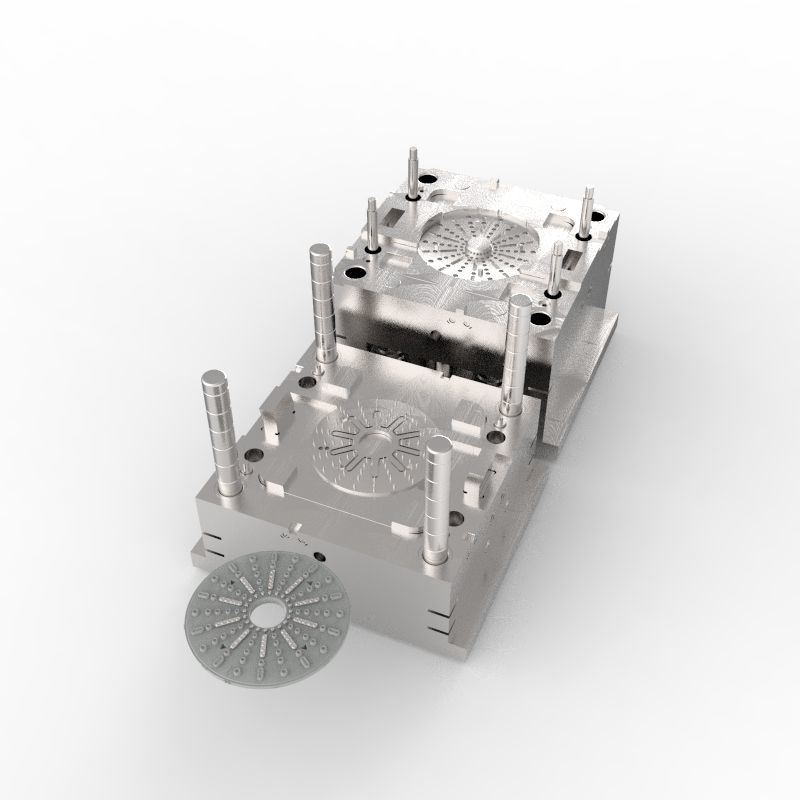

Plastic Injection Mould For Round Top Shower In Bathroom finish by precise CNC.It's well use on personal house,or hotel.We can offer shower mould,shower body or shower products as request.

Product Specification:

Plastic Injection Mould For Round Shower In Bathroom | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | top round shower mold | 1 | S136 | 45# | 40days | 300000 | 100 |

We are not only offer top round shower mould but also offer some related mould like soab case,suspension base mold ,slidding cover mould,friction pad mould,fasten nut mould,marbles mould,non-slip mat mould,decoration ring moulding,decoration cover of suspension base mold,sprayer body injection mould and so on. The cavity can decide according to customer's production capacity.This just some small parts mould from shower,besides these we also offer faucet, toilet lid and towel mould in bathroom.

Plastic Shower Head Mold Manufacturing Process

1. **Design & Engineering**

- Create 3D CAD models of the shower head based on specifications.

- Conduct mold flow analysis (e.g., using Moldflow software) to optimize gate locations and cooling channels.

- Finalize mold design with considerations for parting lines, ejection systems, and slide mechanisms (if undercuts exist).

2. **Material Selection**

- Choose mold steel (e.g., P20, H13, or S136 for corrosion resistance) based on production volume.

- Select plastic material (commonly ABS, PP, or PC) for the shower head.

3. **Precision Machining**

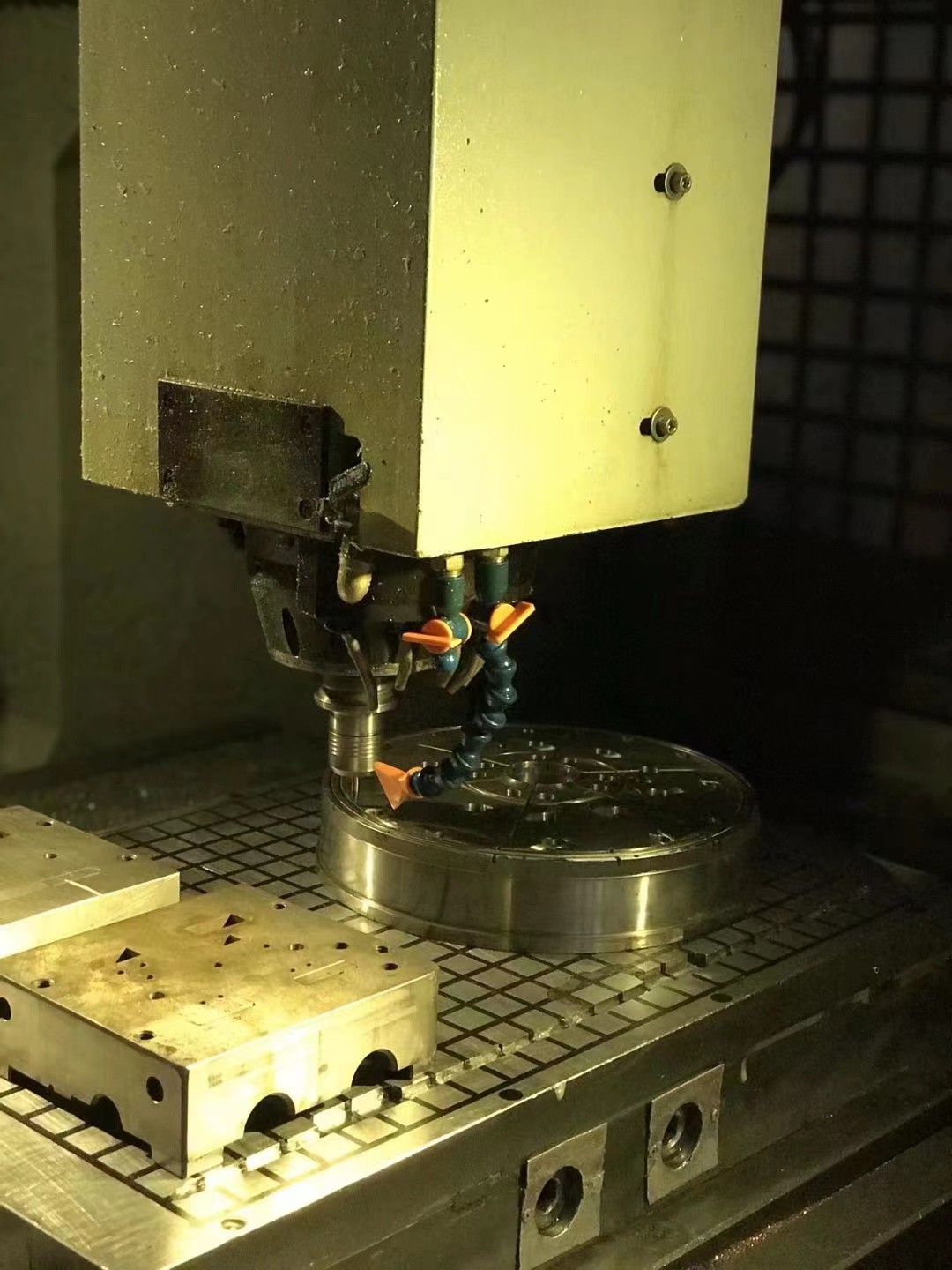

- **CNC Milling**: Machine mold cavities and cores from steel blocks with ±0.01mm tolerance.

- **EDM (Electrical Discharge Machining)**: Form intricate details (e.g., water jet patterns) using copper/ graphite electrodes.

- **Grinding/Polishing**: Achieve mirror-like surface finishes (Ra ≤0.2μm) to ensure smooth shower head surfaces.

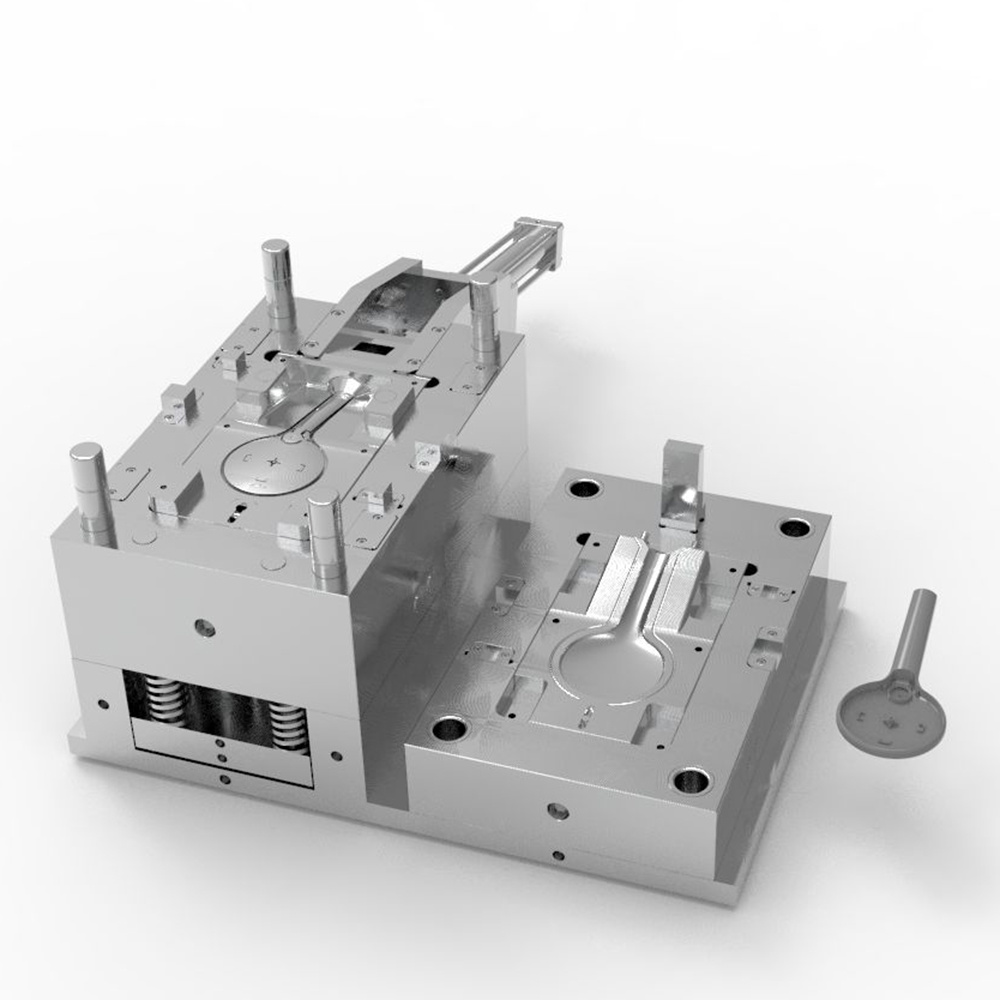

4. **Mold Assembly**

- Integrate cooling channels, ejector pins, and guide systems.

- Assemble core/cavity inserts with mold base (standard: DME or HASCO systems).

- Verify alignment with test fittings.

5. **Trial Injection Molding**

- Mount mold on an injection machine (e.g., 100~300 ton clamping force).

- Adjust parameters: melt temp (200~300°C), injection pressure (80~120 MPa), cooling time.

- Inspect first articles for defects (sink marks, flash, warpage).

6. **Post-Processing**

- Trim excess plastic (runners/gates) manually or via automation.

- Apply secondary processes: ultrasonic welding (for multi-part assemblies), chrome plating (for metallic finishes).

7. **Quality Control**

- Dimensional checks (CMM measurement).

- Flow rate testing (e.g., 8~12 L/min at 3 bar pressure).

- Durability tests (50,000+ cycle tests for pivot mechanisms).

8. **Packaging & Delivery**

- Protect mold surfaces with anti-rust coatings.

- Ship in custom wooden crates with shock-absorbent materials.

**Key Considerations**:

- Cycle time optimization (typically 20~40 seconds per shot).

- Venting design to prevent air traps.

- Modular design for future nozzle pattern changes.

---

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mould For Items In Bathroom Series

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Attached pics are plastic injection shower mould for bangladesh customer and are ready for delivery .Packing by non-fumigation wood crate.