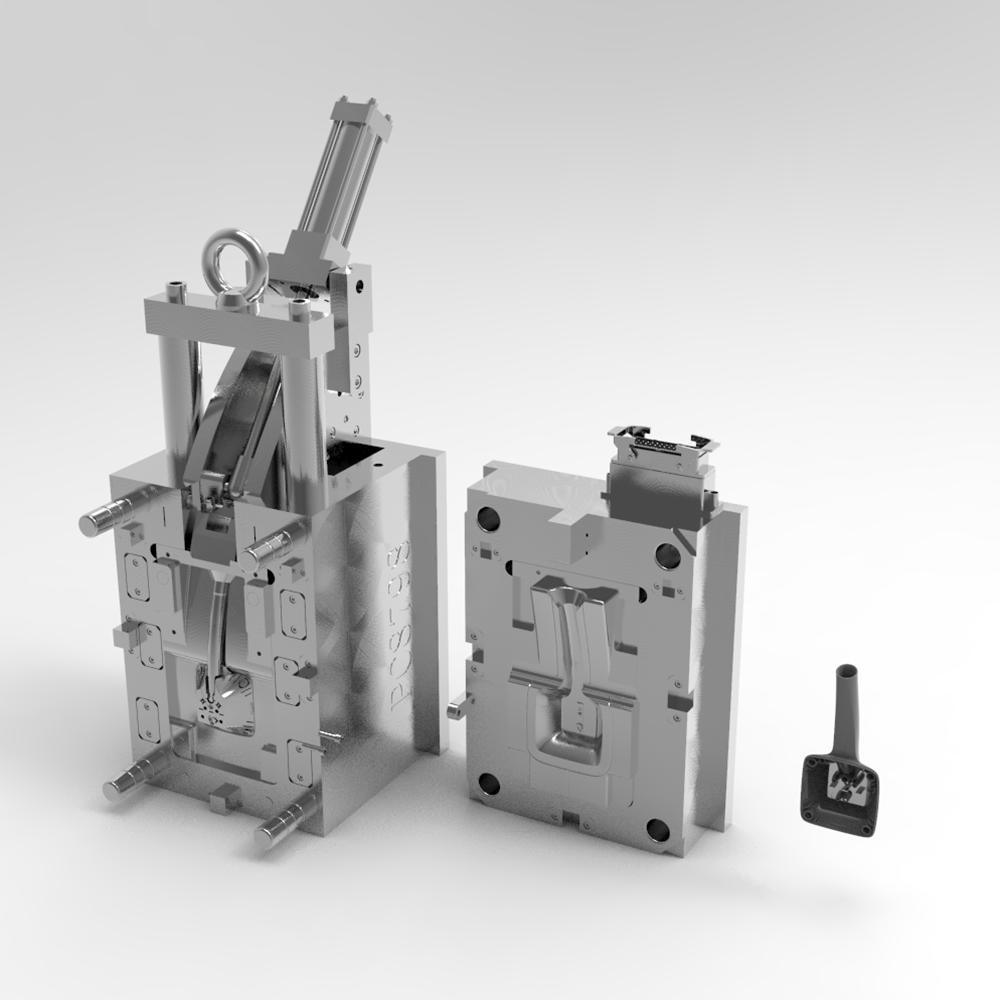

plastic molding manufacturing -fengjin mold industry in xiamen

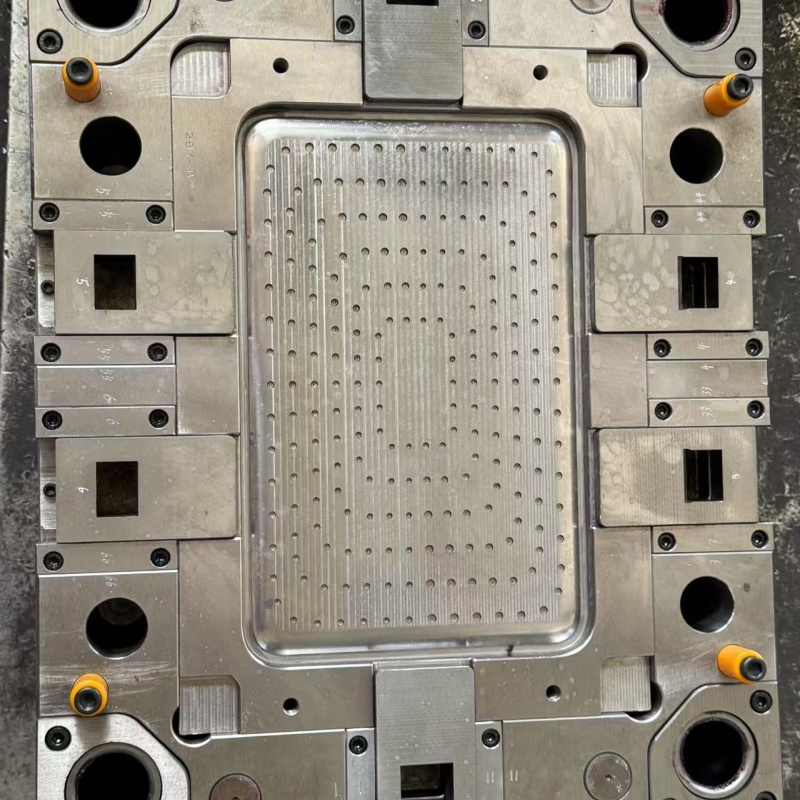

Manufacturing Technique:injection Mould Core:S136

Mould Base :45# steel

Cavity:2

Packing:save packing by crate

Delivery time:90 days for final delivery that customer confirm the samples

We have full line mold producing equipement in our factory for mold production ,assemble and testing the mold.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding company for drainer | 2 | S136 | 45# | 90days | 500000 | 80 |

**Introduction to Plastic Injection Molds for Bathroom Plumbing Systems**

Plastic injection molds play a crucial role in the mass production of high-precision, durable components for bathroom plumbing systems. These molds are used to manufacture a wide range of products, including faucet bodies, showerheads, valve casings, pipe fittings, and other essential plumbing parts.

**Key Features of Bathroom Plumbing Injection Molds**

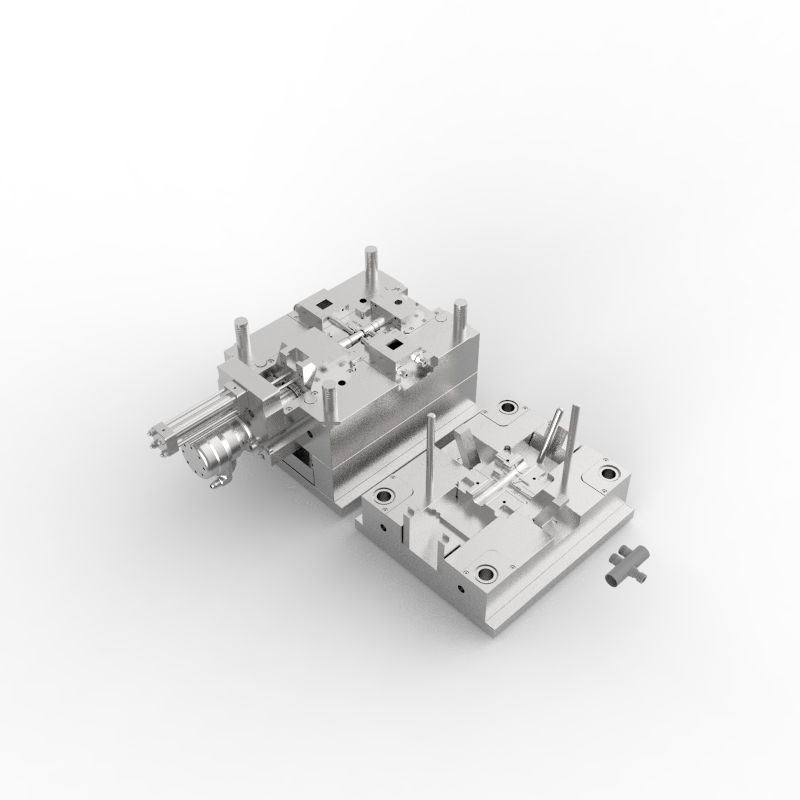

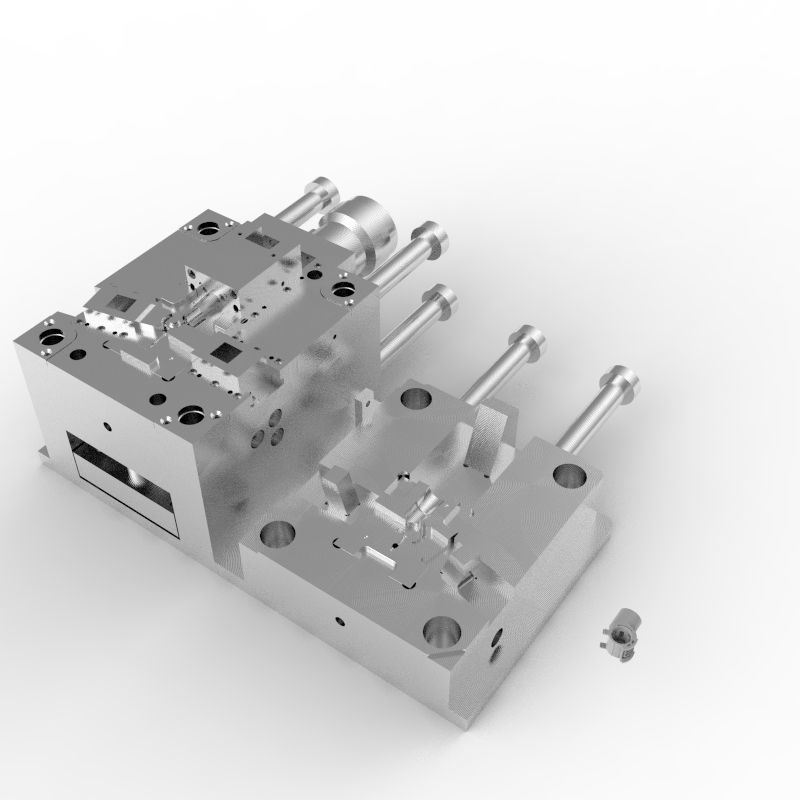

1. **High Precision & Complexity** – Modern injection molds are designed with advanced CAD/CAM technologies to ensure tight tolerances and intricate geometries, meeting the demanding requirements of plumbing systems.

2. **Durability & Longevity** – Made from hardened steel or high-quality aluminum, these molds withstand high-pressure injection cycles, ensuring consistent production over extended periods.

3. **Corrosion & Wear Resistance** – Given the wet and chemically exposed environment of bathrooms, molds are engineered to produce parts with excellent resistance to water, detergents, and mineral deposits.

4. **Efficient Cooling Systems** – Optimized cooling channels reduce cycle times, enhancing productivity while maintaining dimensional stability.

5. **Multi-Cavity & Family Molds** – To improve efficiency, molds often feature multiple cavities or combine different components in a single mold, reducing production costs.

**Materials Used in Plumbing Component Molding**

Common thermoplastics include:

- **PP (Polypropylene)** – Chemical-resistant and flexible, ideal for fittings and connectors.

- **ABS (Acrylonitrile Butadiene Styrene)** – Tough and impact-resistant, used for faucet handles and housings.

- **POM (Polyoxymethylene)** – High stiffness and low friction, suitable for gears and valve mechanisms.

- **PVC (Polyvinyl Chloride)** – Cost-effective and rigid, often used for drain pipes and fittings.

**Applications in Bathroom Plumbing**

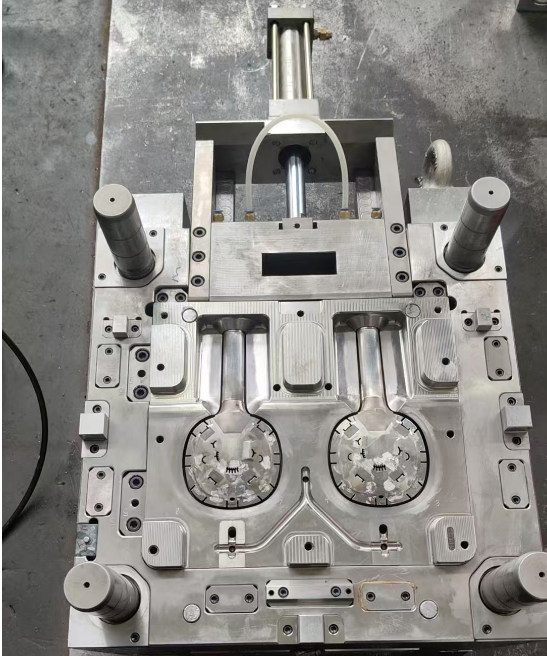

- **Faucets & Mixers** – Complex internal waterways require precision molding to prevent leaks.

- **Shower Systems** – Components like nozzles and diverter valves demand smooth surfaces for optimal water flow.

- **Pipe Fittings & Connectors** – Threaded or snap-fit designs ensure leak-proof connections.

- **Drainage Components** – Molded traps and waste pipes with tight seals prevent blockages.

**Advantages of Injection Molding for Plumbing Parts**

✔ **Mass production with consistent quality**

✔ **Reduced post-processing (minimal finishing required)**

✔ **Design flexibility for ergonomic and aesthetic components**

✔ **Cost-effective for high-volume manufacturing**

Injection molding is the backbone of modern bathroom plumbing manufacturing, enabling the production of reliable, high-performance, and visually appealing components. With advancements in mold technology and material science, manufacturers can meet both functional and design demands efficiently.

Rainshowe mold we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

Some more products we make for other clients