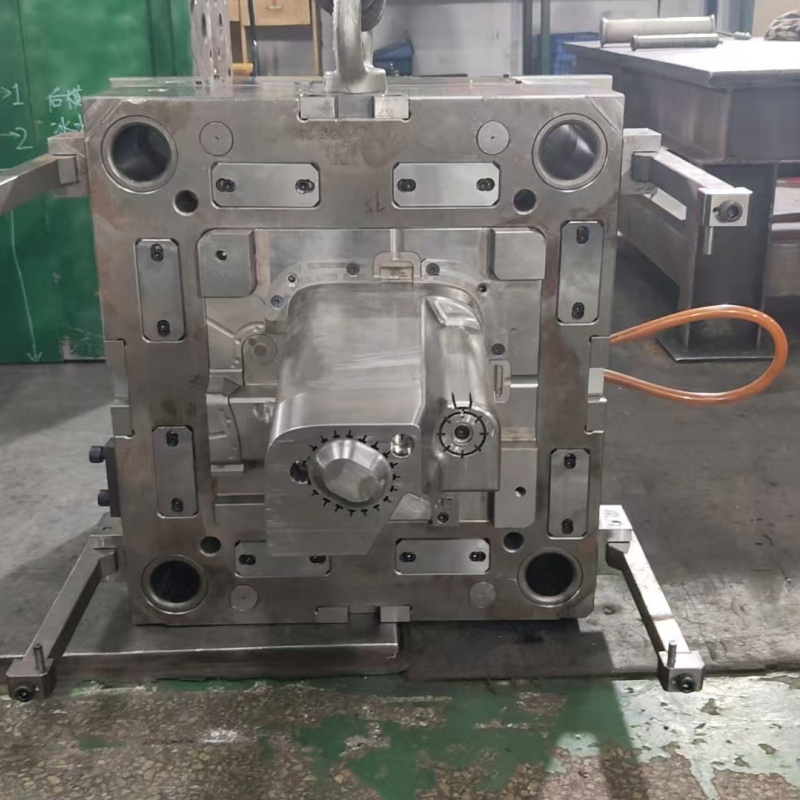

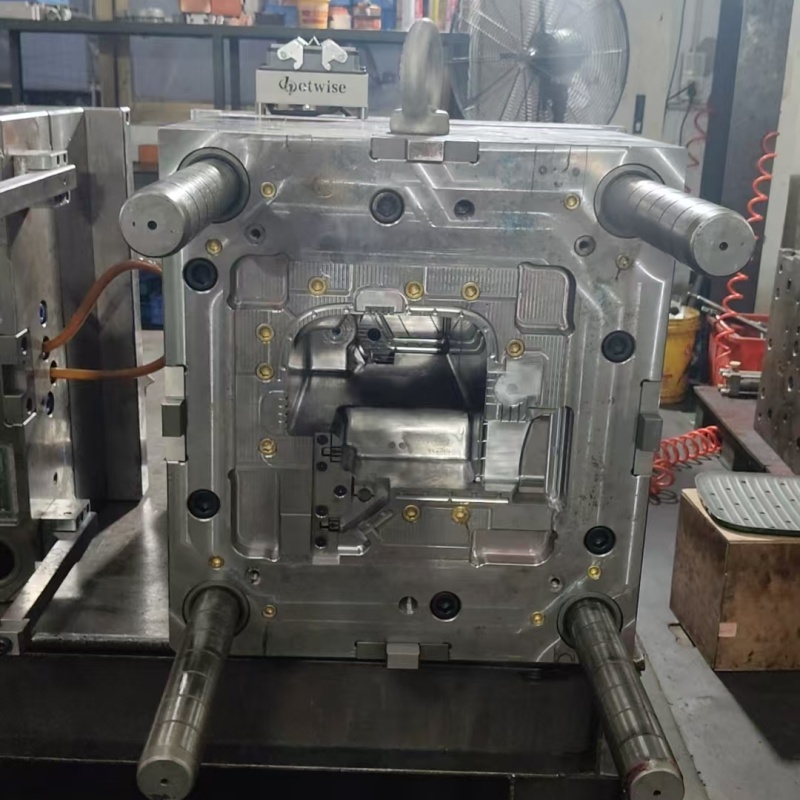

china plastic mold

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Delivery Time:35days for mold trail test

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | injection molding factory | 2 | S136 | 45# | 45days | 400000 | 40 |

### The Injection Molding Process for Plastic Parts

Injection molding is a widely used manufacturing process for producing plastic parts in large volumes. It is highly efficient, repeatable, and capable of producing complex geometries with high precision. The process involves injecting molten plastic material into a mold cavity, where it cools and solidifies into the desired shape. Here is a step-by-step overview of the injection molding process:

#### 1. **Clamping**

The first step involves closing and securely clamping the two halves of the mold (the fixed and moving halves) using a clamping unit. The mold must be tightly closed to withstand the high pressure of the injected material.

#### 2. **Injection**

Plastic material, typically in the form of pellets, is fed into a heated barrel where it is melted and mixed. The molten plastic is then injected into the mold cavity through a nozzle and runner system. The injection pressure and speed are carefully controlled to ensure the cavity is filled completely.

#### 3. **Holding (Dwelling)**

After the cavity is filled, pressure is maintained for a short period to ensure the material packs into the mold and compensates for any material shrinkage as it cools. This step is critical for achieving part density and dimensional accuracy.

#### 4. **Cooling**

The molten plastic inside the mold begins to cool and solidify. Cooling time depends on the material properties, part thickness, and mold design. Efficient cooling is essential for cycle time reduction and part quality.

#### 5. **Mold Opening and Ejection**

Once the part has sufficiently cooled and solidified, the mold opens, and the part is ejected from the mold cavity using ejector pins or other mechanisms. The mold is then ready for the next cycle.

#### 6. **Post-Processing**

After ejection, parts may require additional finishing steps, such as trimming excess material (e.g., sprues and runners), surface treatment, or assembly.

#### Key Advantages of Injection Molding:

- High production efficiency and repeatability

- Ability to produce complex and detailed parts

- Excellent surface finish and part consistency

- Wide range of compatible materials

#### Common Applications:

Injection molding is used across various industries, including automotive, consumer electronics, medical devices, packaging, and household products.

This process is ideal for mass production due to its scalability, cost-effectiveness, and versatility in material selection and part design.

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.

Welcome to visit our factory to know more about our quality and how we work.