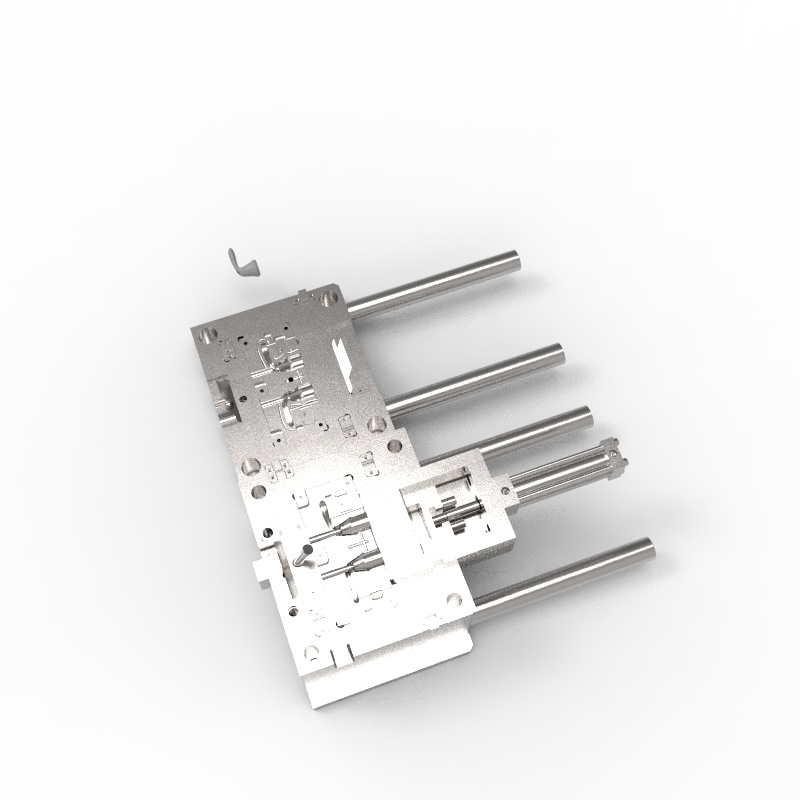

Plastic Automotive Mold Design And Manufacture

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

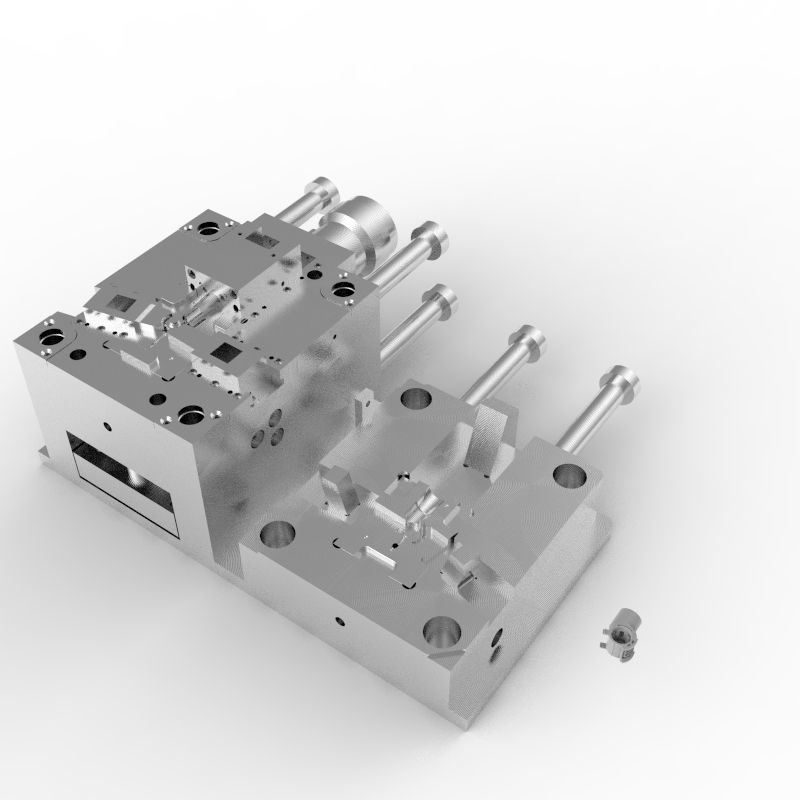

Plastic automotive mold design and manufacture is a complex process that requires a great deal of attention to detail. In order to ensure that the molds and components produced are of the highest quality, there are a number of steps that must be taken. The design process begins with the creation of a 3D model of the part to be produced. This model is then used to create a detailed set of blueprints that will be used to create the mold. The mold is then machined to exact specifications, ensuring that the part will fit correctly and function as intended. Once the mold is finished, it is inspected to ensure that it meets all quality standards.

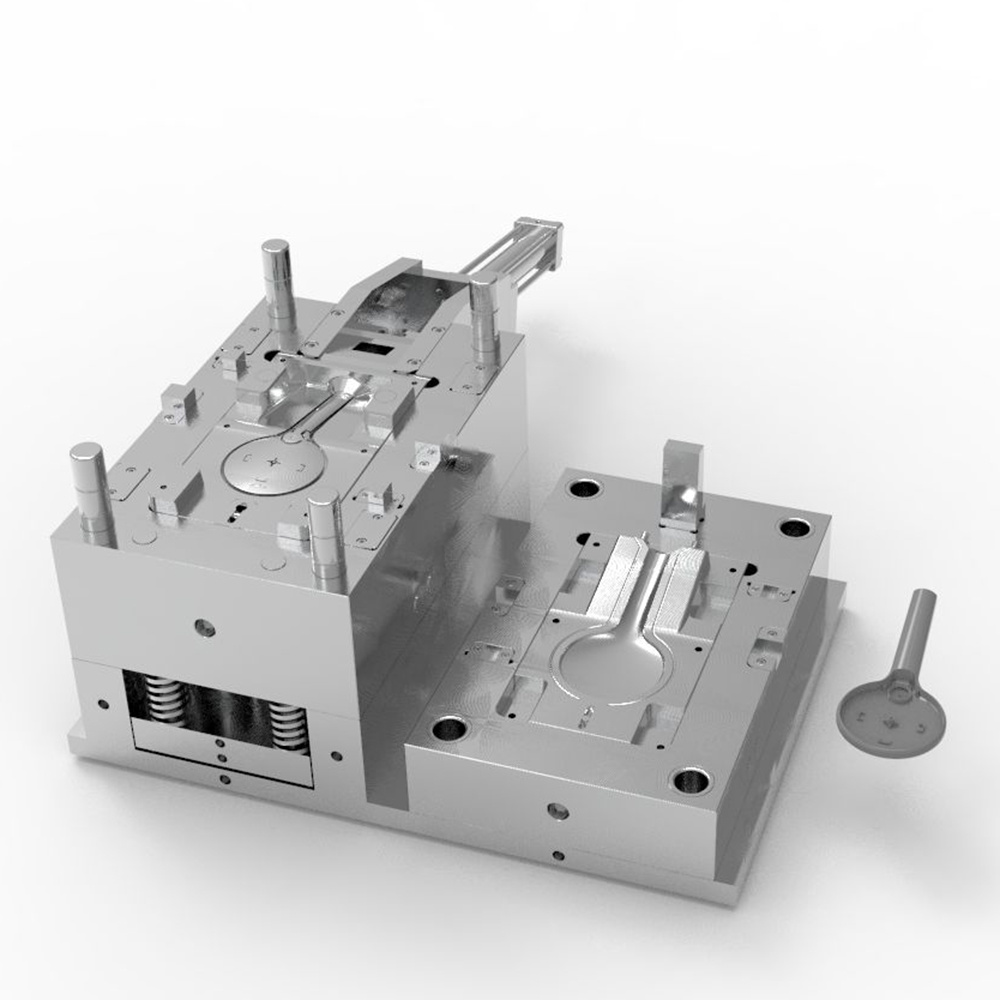

Once the mold is approved, the plastic components can be produced. This process begins with the injection of molten plastic into the mold. The plastic is then cooled and removed from the mold. It is then inspected to ensure that it meets all quality standards. Any imperfections are corrected before the part is ready for use.The next step of the process is the finishing of the part. This includes painting, polishing, and other treatments that are necessary to give the part its desired look and feel. These processes are also inspected to ensure that the part meets the highest standards.

Product Specification:

| Plastic Automotive Mold Design And Manufacture | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic auto mold | 2 | S136 | 45# | 40days | 300000 | 95 |

Once the part is finished, it is ready to be used in the automotive industry. This includes being installed in the vehicle, tested, and evaluated. This process is repeated until the part meets all the necessary requirements.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Automotive Mold Design And Manufacture

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order