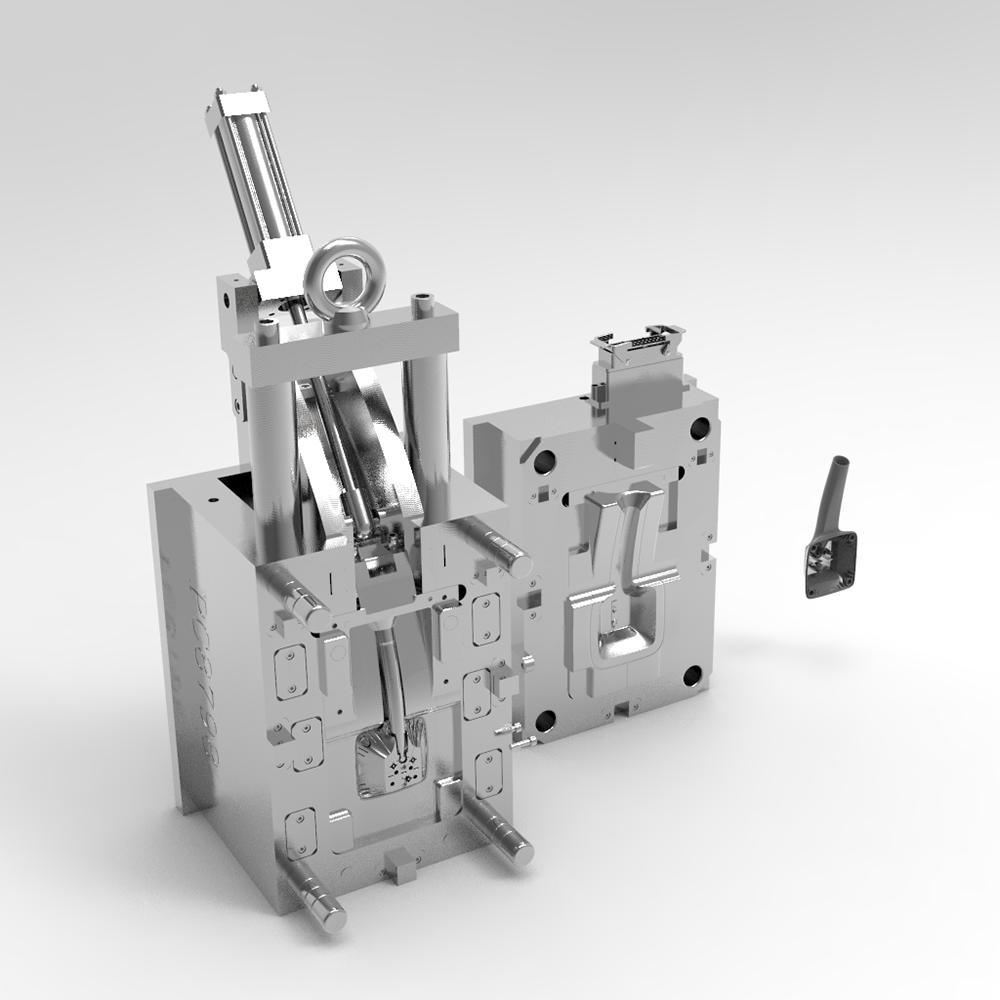

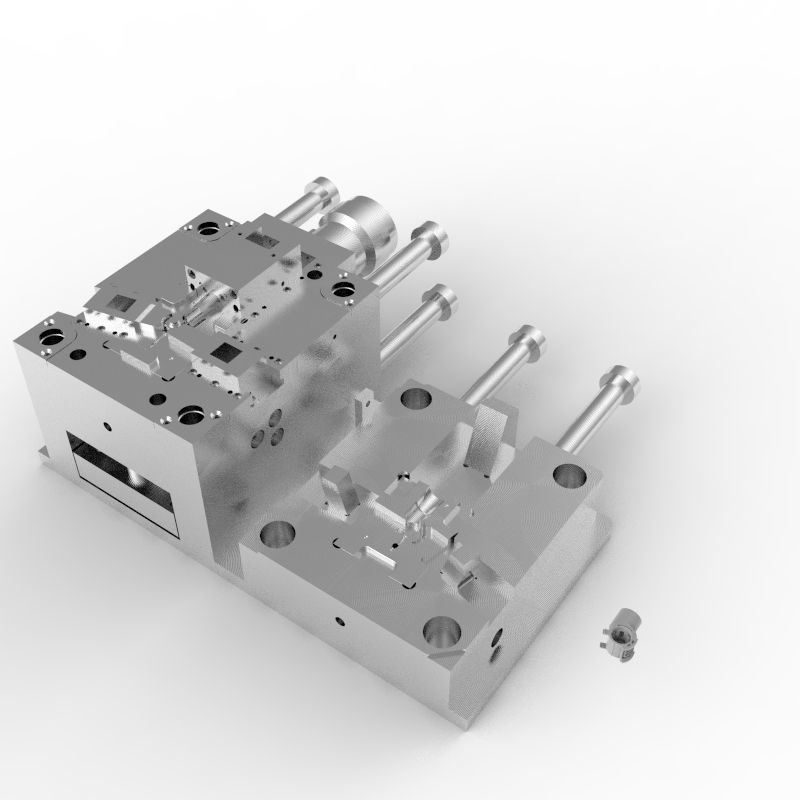

Plastic Injection Mold Industy Make Bathroom Shower Parts Mould

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Bathroom shower parts moulds are essential tools for manufacturing bathroom showers. The moulds are used to shape and form the bathroom shower parts into the desired size and shape. The moulds are usually made from metal and consist of two parts, the main body and the plunger. The main body is the part that holds the liquid, while the plunger is designed to dispense the shower parts.

When manufacturing bathroom shower parts, the moulds are very important. It is important that the moulds are made of the highest quality metal, as this will ensure that the bathroom shower parts are made to the right specifications and that it will last for a long time. The moulds must also be able to withstand the pressures and temperatures of the manufacturing process, as well as the pressures and temperatures of the bathroom shower parts.

The moulds must also be able to provide a perfect fit, so that the bathroom shower parts fit snugly into the bathroom shower. It must also be able to produce a perfect finish, so that the bathroom shower parts look attractive and professional.

Product Specification:

| Plastic Injection Mold Industy Make Bathroom Shower Parts Mould | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | bathroom shower parts mould | 2 | S136 | 45# | 40days | 380000 | 65 |

And we can offer some related products mould like soab case on shower stand and other plastic parts like slidding cover mould,friction pad mould,fasten nut mould,marbles mould,non-slip mat mould,decoration ring moulding,decoration cover of suspension base mold,sprayer body injection mould and so on. The cavity can decide according to customer's production capacity.Some more mould pics we make for your refer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Plastic Injection Mold Industy Make Bathroom Shower Parts Mould

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order