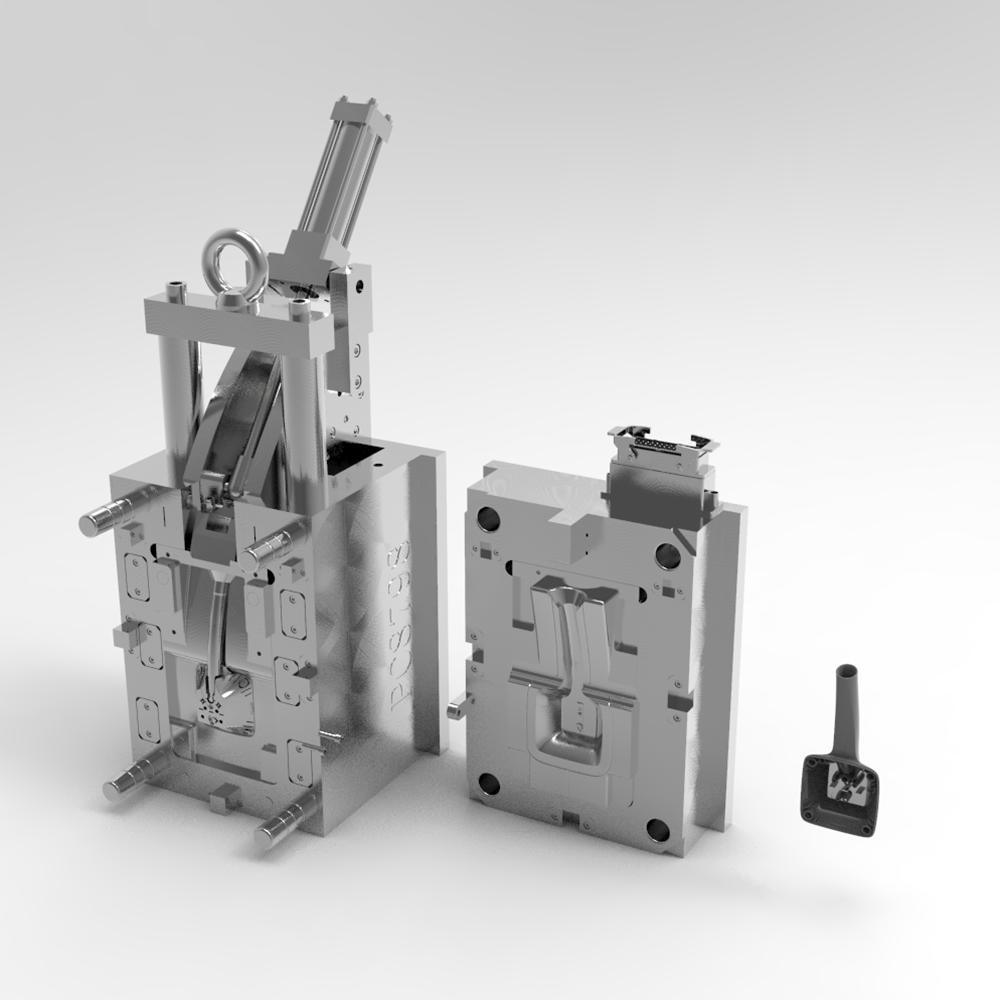

plastic molding manufacturing -fengjin mold industry in xiamen

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:1

**The Application of Plastic Drainage Fittings in Bathrooms**

Plastic drainage fittings have become an essential component in modern bathroom installations due to their durability, cost-effectiveness, and ease of installation. These fittings, typically made from PVC (Polyvinyl Chloride), ABS (Acrylonitrile Butadiene Styrene), or PP (Polypropylene), offer numerous advantages over traditional metal alternatives, making them a popular choice for residential and commercial bathrooms alike.

**Advantages of Plastic Drainage Fittings**

1. **Corrosion Resistance**

Unlike metal pipes, plastic fittings are immune to rust and corrosion, even in high-moisture environments like bathrooms. This ensures a longer lifespan and reduces maintenance costs.

2. **Lightweight & Easy to Install**

Plastic fittings are significantly lighter than metal ones, simplifying transportation and installation. Their flexibility allows for easy cutting and fitting, reducing labor time and costs.

3. **Chemical & Clog Resistance**

High-quality plastic pipes resist chemical reactions with soaps, shampoos, and cleaning agents. Smooth inner walls also minimize buildup, preventing clogs and maintaining efficient drainage.

4. **Cost-Effective Solution**

Plastic drainage systems are generally more affordable than metal alternatives while offering comparable (or superior) performance in bathroom applications.

5. **Noise Reduction**

Plastic absorbs sound better than metal, reducing the noise of running water—a valuable feature in residential bathrooms.

**Common Applications in Bathrooms**

- **Shower Drains**: Plastic linear or point drains provide efficient water drainage while resisting soap scum and hair buildup.

- **Sink & Vanity Drainage**: P-traps and waste pipes made of PVC or PP ensure leak-free connections.

- **Floor Drains**: Plastic floor drains with strainers prevent debris from entering the plumbing system.

- **Bathtub Waste & Overflow Kits**: Lightweight yet durable plastic assemblies simplify bathtub installations.

**Installation Tips**

- Use solvent cement or compression fittings for leak-proof joints.

- Ensure proper slope in pipe routing to facilitate smooth drainage.

- Regularly clean strainers and traps to maintain optimal flow.

**Conclusion**

Plastic drainage fittings provide a reliable, economical, and low-maintenance solution for bathroom plumbing systems. Their resistance to corrosion, ease of installation, and versatility make them an ideal choice for modern bathrooms. As technology advances, we can expect even more innovative plastic solutions to enhance drainage efficiency and sustainability.

We have full line mold producing equipement in our factory.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic molding company for drainer | 1 | S136 | 45# | 45days | 200000 | 95 |

We can help to make ultroultrasonic mold for customer as well.

Other products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate