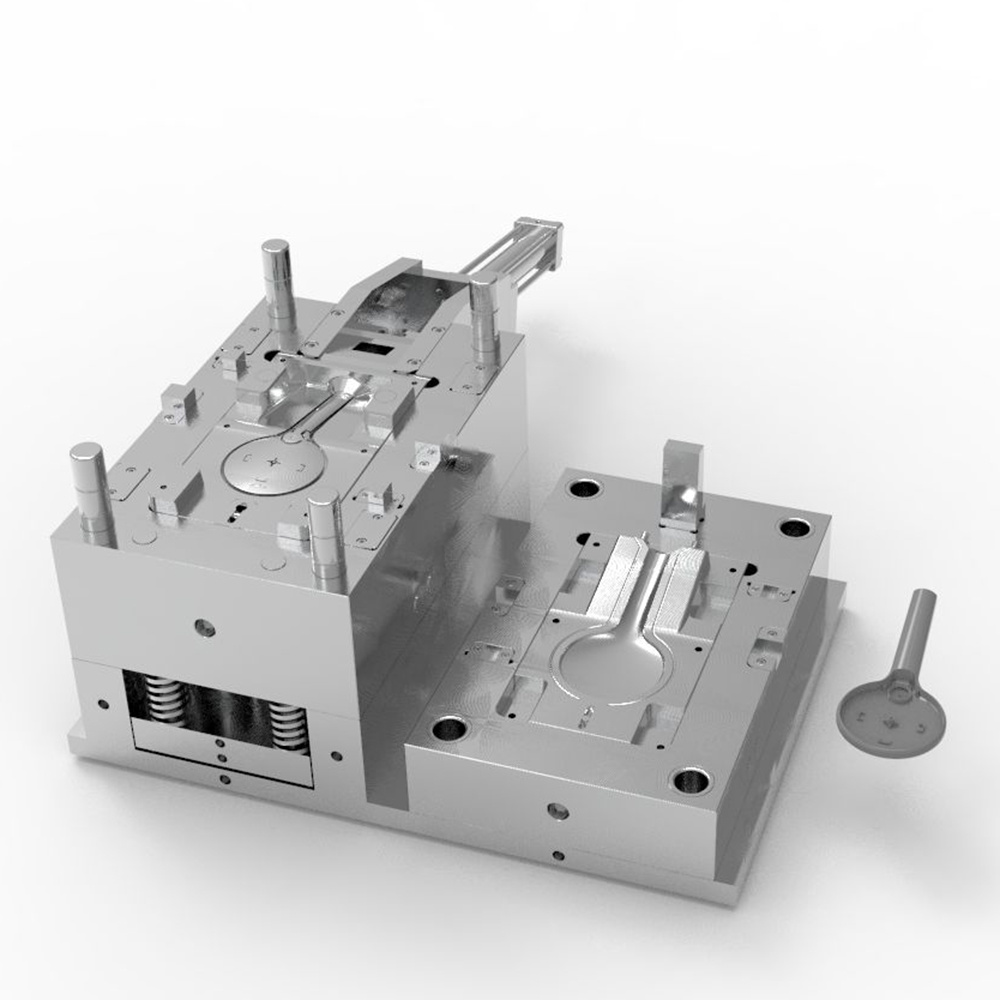

Medical Injection Mold For Plastic Goggle Mould

Manufacturing Technique:injection plastic

Mould Core:S136

Mould Base :45# steel

Cavity:1

Factory Location:Xiamen,China

Supply Capacity: 50sets/month

Product Specification:

| Medical Injection Mold For Plastic Goggle Mould | |||||||

|

factory |

mould name |

mold cavity |

mold core |

mold base |

mold delivery time |

shot(times) |

circle time(second) |

|

fengjin |

plastic goggle mould |

1 |

S136 |

45# |

40days |

300000 |

55 |

The process of creating plastic goggles involves a mould. The mould is usually made of a hard material such as metal or plastic. It is designed to create the shape of the goggles, which is then filled with the plastic material. The mould is then heated and cooled in order to create the desired shape.Once the mould is finished, the plastic is poured into the mould and left to cool. After the plastic is cooled, it is removed from the mould and the goggles are ready to be used.

The plastic goggles mould is an important part of the production process, as it helps to ensure the quality of the goggles. The mould needs to be accurate and precise in order to create a product that is safe and reliable. The mould also needs to be able to withstand the heat and pressure of the plastic as it is poured into it.The plastic goggles mould is also important for creating a variety of different styles of goggles. Different shapes and sizes can be created with the mould, allowing for a wide range of different looks. This means that the goggles can be customized to fit the needs of the user.The plastic goggles mould is also important for creating a variety of different colors. Different colors can be created by mixing different types of plastic together. This means that the goggles can be customized to match any outfit or style.

The plastic goggles mould is an important piece of equipment for any company that manufactures goggles. It helps to ensure that the goggles are made with the highest quality materials and that they are safe and reliable. The mould also helps to ensure that the goggles are made to the correct specifications and that they are durable and long-lasting. It is also important to keep the mould clean and well-maintained in order to ensure that the goggles are safe and reliable

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Medical Injection Mold For Plastic Goggle Mould,we also custom other plastic mould like shower mould and other bathroom related products

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate