Plastic injection molders since 1998

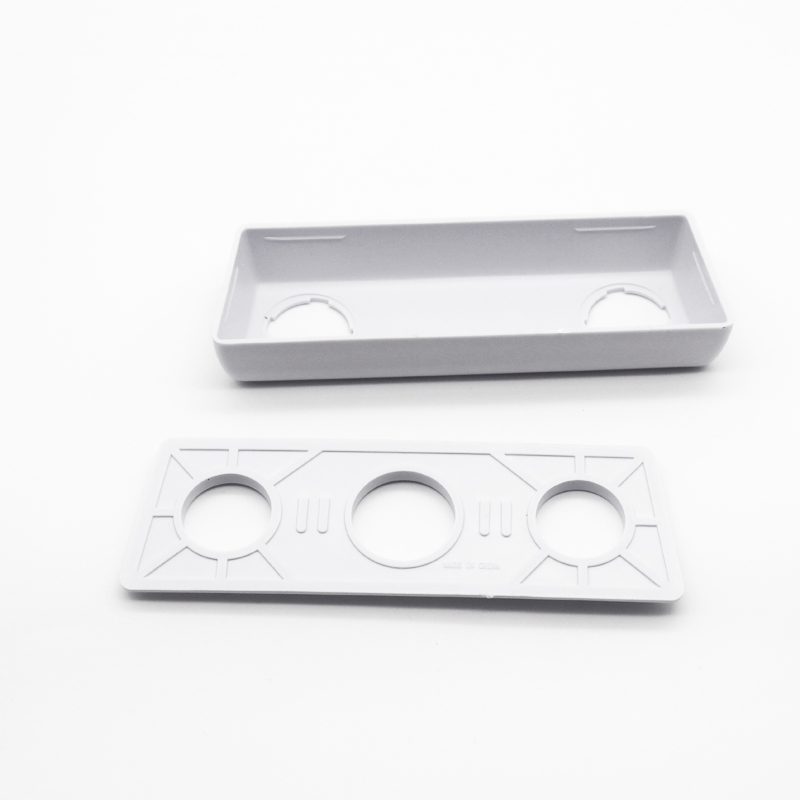

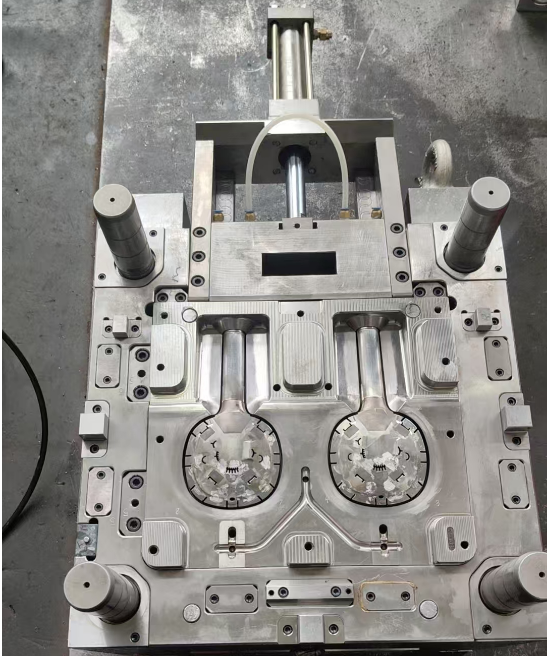

Manufacturing Technique:plastic injection mould

Runner:Cold

Mould Core:S136

Mould Base :C50

Cavity:2

Factory Location:Xiamen,China

Supply Capacity: 55-65sets/month

Kep Words:plastic injection mould ,injection molding factory

Look around your bathroom. Chances are, many of the sleek, functional, and hygienic items you use daily owe their existence to precision-engineered plastic bathroom molds. These specialized tools are the silent workhorses of manufacturing, transforming raw plastic resins into the essential fixtures that make our modern bathrooms clean, comfortable, and convenient. Let's explore the everyday products and applications they make possible:

Core Products Shaped by Plastic Bathroom Molds:

Shower & Bath Solutions:

Acrylic/PMMA Tubs: The classic drop-in, alcove, corner, and especially popular freestanding tubs are formed in large, complex molds via injection molding or thermoforming over a mold. They provide a glossy, durable, and warm-to-the-touch surface.

Rotomolded Tubs: Larger, uniquely shaped, or more complex one-piece freestanding tubs might be made from polyethylene (PE) using rotational molding.

Shower Trays/Bases: From simple rectangles to luxurious walk-in designs with integrated textures (like non-slip surfaces) and drain channels, these are predominantly made from acrylic/PMMA, ABS, or fiberglass-reinforced plastics using injection molding.

Bathtubs:

Shower Walls & Liners: Smooth, textured, or faux-tile finish panels, often made from ABS, PVC, or acrylic composites, are injection molded for easy installation and water resistance.

Shower Enclosures & Doors: While the glass is separate, the frames, handles, hinges, soap dishes, and shelves attached to them are frequently injection molded from durable plastics like ABS or PP.

Showerheads & Faucet Handles: The main bodies and ergonomic handles of many modern showerheads and faucets are precision injection molded, allowing for intricate water channel designs and comfortable grips.

Sink & Vanity Essentials:

Countertop Basins/Vessel Sinks: Stylish above-counter sinks, especially modern designs in acrylic or solid surface materials, are formed in molds.

Integrated Sink Tops: Vanity tops with the sink basin seamlessly integrated into the counter surface (often made from engineered stone composites or acrylic solid surface) are cast or formed using molds.

Undermount Sink Bowls: While often ceramic, many modern undermount sinks are made from durable, stain-resistant composite materials formed in molds.

Pedestals & Vanity Cabinets: Though the main structure might be wood or MDF, doors, drawer fronts, handles, decorative panels, and legs on modern vanities are commonly injection molded from plastics like ABS or PVC, offering design flexibility and moisture resistance.

Toilet Components:

Toilet Seats & Covers: Perhaps the most universally recognized molded plastic bathroom item. Made from PP (Polypropylene) or ABS via injection molding, they come in countless shapes, colors, and features (soft-close, quick-release, antimicrobial).

Toilet Tanks & Cisterns: While the bowl is often ceramic, the tank cover, flush buttons/levers, and internal components (like float valves, flappers - though some are rubber) are predominantly injection molded plastics.

Bidets & Smart Toilet Housings: The plastic outer shells and functional components of modern bidet attachments and integrated smart toilets rely heavily on injection molding.

Squat Toilet Pans: In regions where they are common, plastic squat toilet pans are typically rotationally molded from PE for durability and cost-effectiveness.

Accessories & Hygiene Products:

Soap Dispensers & Dishes: From wall-mounted units to countertop dishes, these are almost exclusively injection molded.

Toothbrush Holders & Cups: Simple yet essential items, mass-produced via injection molding.

Toilet Brush Holders & Brushes: The handles, bristle mounts, and containers are molded plastic.

Towel Bars, Rings & Hooks: The functional holders themselves are often chrome-plated metal, but the end caps, mounting brackets, and screw covers are plastic injection molded parts.

Waste Bins: Bathroom-sized bins, often with foot pedals or touchless lids, are made using injection molding or blow molding.

Bath Mats & Non-Slip Pads: While soft ones are textile, rigid or semi-rigid anti-slip shower/bath mats are injection molded or thermoformed.

Children's Bath Steps & Seats: Safety products designed for kids are robustly injection molded from durable, easy-to-clean plastics.

Why Plastic Molds are Essential for These Everyday Items:

Complexity & Detail: Molds can create intricate shapes, undercuts, textures (wood grain, stone), and integrated features (soap holders, non-slip patterns, mounting points) impossible with other methods.

Mass Production & Consistency: Injection molding allows for high-volume, rapid production of identical parts, ensuring consistent quality and availability of affordable products.

Material Versatility: Molds are designed for specific plastics (Acrylic/PMMA, ABS, PP, PE, PVC, composites), each chosen for properties like durability, chemical resistance, heat tolerance, surface finish, and cost.

Hygiene & Cleanability: Molded plastic products offer non-porous surfaces (especially acrylic and solid surface), making them resistant to stains, mold, mildew, and easy to clean – crucial for bathroom environments.

Design Freedom & Innovation: Molds enable designers to create ergonomic shapes, modern aesthetics, and innovative features (like integrated LED lighting channels or hidden plumbing access points) that enhance user experience.

Durability & Longevity: Precision molds ensure parts are dimensionally stable and free of defects, contributing to the long life of the final product. High-quality plastics resist chipping, cracking, and fading.

Invisible Impact, Tangible Convenience:

From the moment you step onto your shower base to when you put down the toilet seat, plastic bathroom molds are intimately involved in your daily routine. They are the foundational technology enabling the production of the hygienic, functional, and aesthetically pleasing plastic components that define the modern bathroom. These molds transform basic plastics into the essential, durable, and well-designed products that make our personal sanctuaries both practical and pleasant. Their unseen precision directly shapes the comfort and convenience we experience every day

Plastic mold design refers to the process of creating a mold that is used to shape plastic materials into a desired form. It involves designing the mold structure, creating cavity and core components, and considering factors such as material flow, cooling, and ejection. Here are some key steps in plastic mold design: 1. Product Design: Understand the requirements and specifications of the plastic part that needs to be molded. Consider factors such as dimensions, shape, and functionality. 2. Mold Structure Design: Determine the type of mold required, such as a two-plate mold, three-plate mold, or hot runner mold. Design the mold structure including the parting line, gating system, and ejection system. 3. Cavity and Core Design: Create the cavity and core components of the mold. Consider factors such as draft angles, surface finish, and tolerances to ensure proper plastic flow and easy ejection. 4. Runner and Gate Design: Design the runner system that delivers molten plastic from the injection molding machine to the mold cavity. Determine the gate location and size to control the flow of plastic into the mold. 5. Cooling System Design: Incorporate a cooling system into the mold to control the temperature and solidification of the plastic. Design cooling channels or inserts to ensure uniform cooling and minimize cycle time.

Product Specification:

| injection mold manufacturer for bathroom products | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | cold runner mold | as customized | S136 | C50 | 50days | 2000000 | according to products |

For mould customized,we can make in a wide range include sanitary,sports,household appliances,car parts and so on.Below are some parts we make for our customer

Beside mold,we also offer ready products as customer request,we can offer products for bathroom and the kitchen.This is our injection area on third floor,inspect and packing the plastic parts and warehouse also in this floor

Hand shower mould is one of our original product,we are super professional on this,we can offer design service and can help customer to double check their drawing before molding,we use S136 as mold core and No.45 # steel for mold base.We make molds for some big company like runner group,solex,moen,kohler,toto,jomoo,schneider and so on.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate