The K Show in Düsseldorf, Germany, is the world's premier trade fair for plastics and rubber. At the very core of this vast industry lies a critical discipline: **mold and tool making**. A mold is more than just a tool; it is the precise, high-tech womb where plastic products are born. It defines the product's form, function, quality, and ultimately, the efficiency and profitability of the entire manufacturing process.

The K Show is the undisputed global stage where the future of mold technology is unveiled and shaped.

**Why Molds are Central to the K Show**

Without advanced molds, the revolutionary polymers and processing machines showcased at the K Show would remain unrealized potential. The mold is the crucial link between raw material and finished part. At the K Show, visitors can explore the entire ecosystem of mold-making, witnessing how innovation in this field drives progress across all sectors—from automotive and medical to packaging and electronics.

**Key Trends and Innovations in Mold Technology at K Show**

**1. Precision & Complexity through Digitalization:**

* **Industry 4.0 & IoT:** Modern molds are "smart." They are equipped with sensors that monitor temperature, pressure, and wear in real-time. This data integrates with production systems for predictive maintenance, minimizing downtime and ensuring consistent, high-quality output.

* **Additive Manufacturing (3D Printing):** K Show highlights the use of 3D printing for creating conformal cooling channels within mold cores. These intricate channels follow the contour of the mold cavity, drastically reducing cooling times and cycle times while eliminating part warpage. Companies also showcase 3D-printed inserts for prototyping or low-volume production of complex parts.

**2. High-Performance Materials & Surfaces:**

* **Advanced Steel Alloys:** Exhibitors present new grades of tool steels offering superior hardness, thermal conductivity, and corrosion resistance, extending mold life even when processing abrasive or corrosive polymers.

* **Surface Engineering:** Innovative coatings and treatments like **PVD (Physical Vapor Deposition)** and **DLC (Diamond-Like Carbon)** are featured. These ultra-hard, low-friction surfaces reduce release problems, resist wear, and allow for easier demolding of sticky materials, further speeding up production cycles.

**3. Efficiency & Sustainability by Design:**

* **Lightweighting:** Molds are engineered to help produce thinner, lighter-weight parts without compromising strength—a critical demand in the automotive and packaging industries to save material and reduce energy consumption.

* **Molds for Recyclates:** With a strong focus on the circular economy, K Show exhibitors demonstrate mold designs optimized for processing recycled plastics. These designs account for the often higher viscosity and varying flow characteristics of recyclates, ensuring high-quality parts from sustainable materials.

**4. Integrated Systems and Automation:**

* **Quick-Change Systems:** Molds are designed for rapid exchange in injection molding machines, enabling highly flexible, just-in-time manufacturing with minimal machine idle time.

* **Ready for Automation:** Modern molds are built with integrated robotics in mind, featuring standardized interfaces for automated part removal, inspection, and assembly.

**What to See at the K Show**

Visitors to the K Show should look for:

* **Live Demonstrations:** See molds in action on injection molding machines, producing complex parts with cycle times measured in seconds.

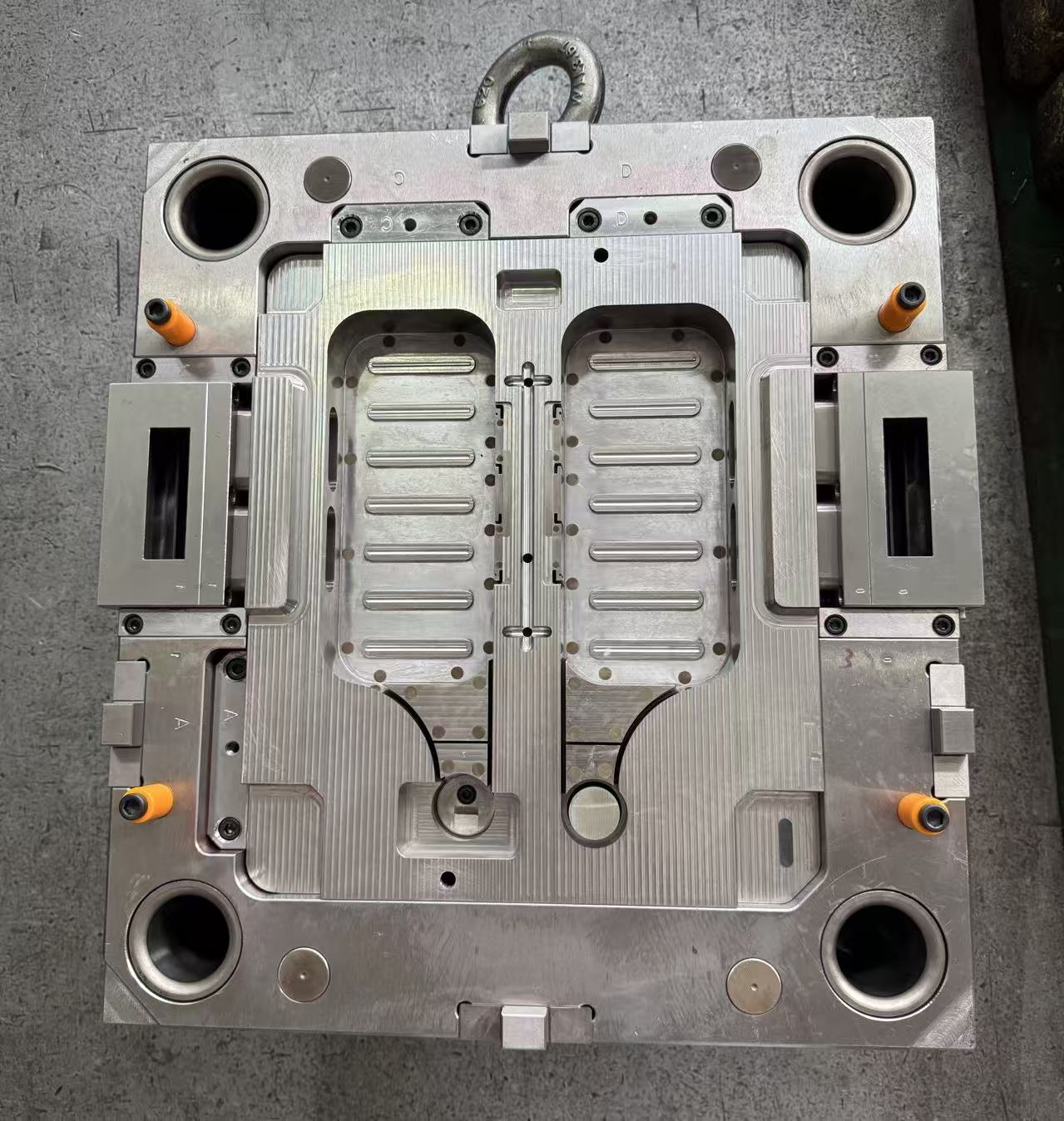

* **Finished Parts alongside the Mold:** Many exhibitors display the final product next to the mold that created it, brilliantly illustrating the direct connection between tooling precision and product excellence.

* **Specialist Exhibitors:** The fair brings together the world's leading mold-makers, from large-scale producers to niche specialists for micro-molding or large-format parts.

* **Software Pavilions:** Discover the latest in **CAD/CAM/CAE software** for mold design (like Siemens NX, Dassault Systèmes) and mold flow analysis, which simulates the filling process to eliminate defects before a single piece of steel is cut.

**Conclusion**

The K Show is an unparalleled opportunity to understand that the mold is not merely a component but a **strategic asset**. The innovations showcased here in mold-making are fundamental to achieving greater productivity, sustainability, and design freedom in the global plastics industry. For anyone involved in product design, engineering, or manufacturing, a visit to the halls dedicated to mold and tooling at the K Show is an essential journey to the heart of industrial innovation.