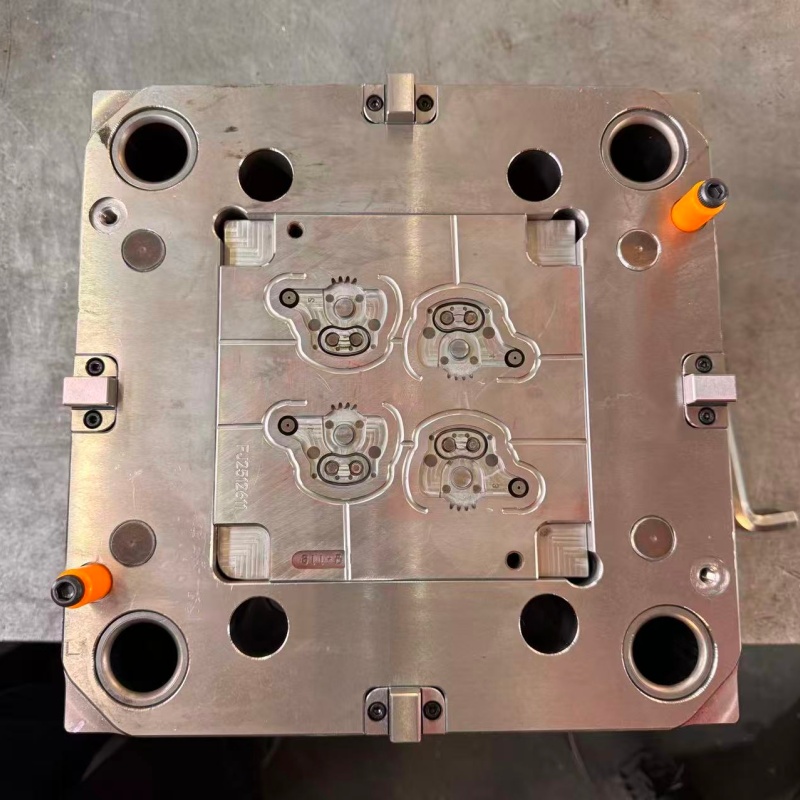

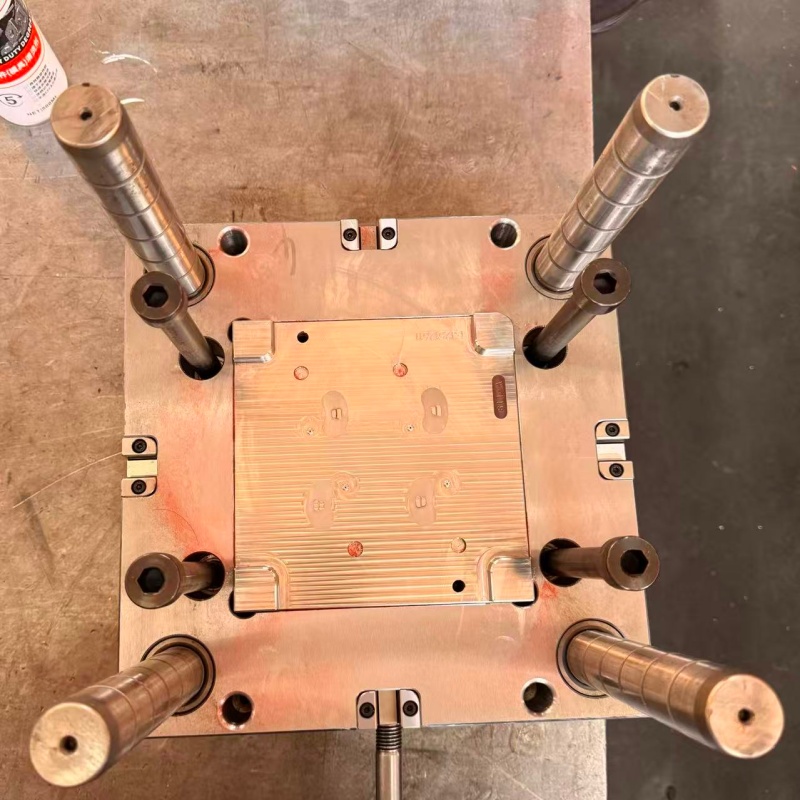

Topest quality of mould base and mold core that we offer,and also the thickness to ensure the mould quality

Manufacturing Technique:injection

Mould Core:S136H

Mould Base :45# steel

Cavity:4

Delivery time:45days after 3D drawing confirm

part of the working area by cnc in our factory

Product Specification:

Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | injection mould manufacturer | 4 | S136 | 45# | 45days | 400000 | 40 |

2026 Outlook for the Injection Molding Tooling Industry

The injection molding tooling industry is poised for robust growth and transformative evolution in 2026, driven by global manufacturing upgrading, technological innovation, and surging demand across key application sectors. As a cornerstone of modern manufacturing, injection molding tooling will embrace intelligence, greenization, and precision as its core development pillars, unlocking new value in the global industrial chain.

Market expansion will be fueled by multi-dimensional demand drivers. Globally, the injection molding market is projected to reach $312.66 billion in 2026, with a compound annual growth rate of 5.0% through 2036, directly boosting the demand for high-performance molding tooling . In China, the market for plastic injection products is expected to hit 480 billion yuan, with automotive parts (28.3%), electronic appliances (24.7%), and medical devices (7.1%) emerging as the top application segments . The rapid development of new energy vehicles—particularly the need for lightweight components and precision battery structures—and the proliferation of 5G devices and wearable tech will drive specialized tooling requirements, such as microcellular foaming molds and multi-material co-injection tooling .

Technological innovation will redefine industry standards in 2026. Intelligent tooling integrated with AI algorithms and real-time monitoring systems will become mainstream, enabling predictive maintenance, process parameter optimization, and a 23.8% increase in production efficiency . The adoption of all-electric injection molding machines will rise to 35.8%, paired with servo-driven systems (45.2%), enhancing dimensional accuracy and reducing energy consumption by 18.6% . Precision tooling capabilities will advance to micron-level tolerances (±0.005 mm), supported by high thermal conductivity materials like beryllium copper and nano-composite steels . Patent activity will remain vigorous, with over 12,000 new patents globally focusing on energy efficiency and precision control, including gas backflow prevention designs and thermal management innovations that cut material waste by 15% and heat loss by 27% .

Sustainability will transition from a trend to a core business imperative. The application of biodegradable materials in tooling will jump from 15.8% to 22.1%, while circular economy initiatives will drive 89.7% waste recycling rates . Mold manufacturers will adopt eco-friendly processes such as "treasured sand molding" to reduce dust emissions by 50%, and invest $2.5 billion globally in carbon reduction technologies, lowering the industry's carbon intensity by 12.8% year-over-year . Green tooling design—focused on material efficiency, energy conservation, and recyclability—will become a key differentiator in market competition .

Industry consolidation and regional clustering will accelerate in 2026. In China, industrial clusters in the Yangtze River Delta (41.2% of national output) and Pearl River Delta (26.7%) will deepen collaboration, with inter-enterprise supporting rates reaching 85.3% . Over 50 shared innovation parks will be established nationwide, increasing industry concentration by 20% . Domesticization of high-end tooling will make significant strides, with China's local production rate of precision molds rising to 72.4%, reducing reliance on imports for critical components . Meanwhile, global supply chain restructuring will see capacity shifts totaling 3.2 million tons, primarily from central to western China, creating new growth opportunities for regional tooling manufacturers .

Despite promising prospects, the industry will face challenges including raw material price volatility, stricter environmental regulations, and international trade frictions . However, the expanding application landscape—from semiconductor packaging to medical microfluidic chips—and ongoing technological breakthroughs will offset these risks.

In summary, 2026 will mark a pivotal year for the injection molding tooling industry, characterized by intelligent upgrading, green transformation, and specialized development. Enterprises that prioritize R&D investment, embrace digitalization, and align with sustainable practices will thrive in this dynamic market, solidifying the industry's role as a backbone of global advanced

Other plastic injection mould products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom.