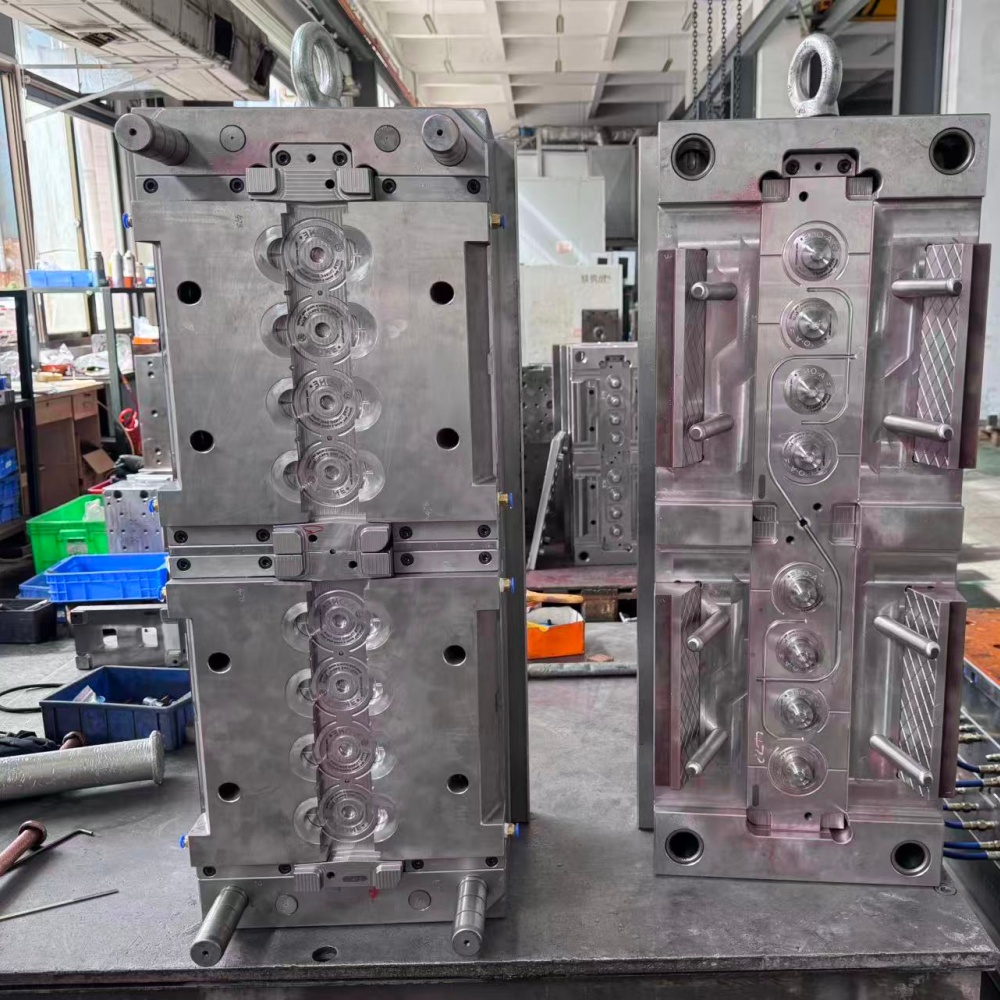

injection molding plastic from xiamen fengjin mold industry

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

Cavity:8

Introduction to the Production of Reel Molds

Reel molds are specialized tools engineered for manufacturing high-precision reels used in industries like electronics, fishing, and textile. Their production combines advanced engineering, precise machining, and strict quality control to ensure durability, dimensional accuracy, and consistent performance of the final reel products.

The production process begins with design and modeling, where engineers analyze the reel’s specifications (size, load capacity, material) and use CAD software to create 3D models of the mold. This stage optimizes cavity structure, cooling channels, and ejection systems to avoid defects like warping or uneven filling during injection molding.

Next comes material selection, a critical step that directly impacts the mold’s lifespan and performance. Common materials include pre-hardened steel (for low-volume production), H13 tool steel (for high-temperature resistance and wear), and stainless steel (for corrosion resistance in harsh environments). The chosen material is then cut into rough blanks via sawing or plasma cutting.

Precision machining follows, utilizing advanced equipment to shape the mold with micron-level accuracy. CNC milling and turning handle the basic contouring, while EDM (Electrical Discharge Machining) and wire cutting refine complex cavities and fine features that traditional machining cannot reach. This stage ensures the mold’s surfaces are smooth and dimensions align perfectly with the design.

After machining, heat treatment is applied to enhance the material’s hardness and toughness. Processes like quenching and tempering reduce internal stress, prevent deformation during use, and extend the mold’s service life—critical for withstanding repeated injection cycles.

The final steps include polishing, assembly, and testing. The mold’s cavity and core are polished to a mirror finish to ensure the reel’s surface quality, then assembled with guide pins, cooling systems, and ejection mechanisms. Rigorous testing involves test injections to check for dimensional accuracy, surface defects, and mold functionality. Adjustments are made until the mold produces reels that meet all technical requirements.

From design to final testing, every step in reel mold production adheres to strict industry standards, making these molds indispensable for efficient, high-quality reel manufacturing across diverse sectors.

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | xiamen mould manufacturer | 8 | S136 | 45# | 45days | 400000 | 40 |

Other plastic injection mould products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom.