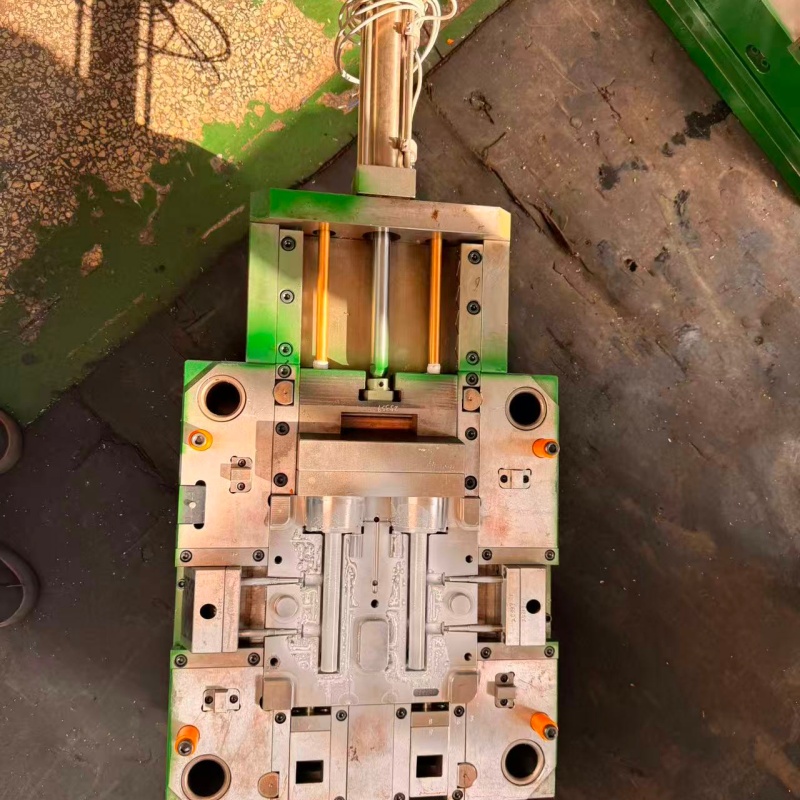

injection mold design and production in xiamen,China

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

C

Introduction to the Production of Plastic Products

Plastic products have become ubiquitous across consumer, industrial, and medical sectors due to their versatility, cost-effectiveness, and customizable physical properties. The production process of plastic products is a systematic workflow that integrates material selection, mold design, molding, post-processing, and quality control, with each stage playing a critical role in ensuring final product performance and compliance with industry standards.

1. Raw Material Selection and Preparation

The first step in plastic product production is selecting the appropriate polymer resin, which is determined by the product’s intended use, mechanical requirements, and environmental exposure. Common raw materials include polyethylene (PE) for flexible containers, polypropylene (PP) for durable household items, acrylonitrile butadiene styrene (ABS) for structural components, and polycarbonate (PC) for transparent, impact-resistant products like safety goggles.

Before molding, raw resin pellets are dried to remove moisture, which can cause defects such as bubbles or surface blemishes in the final product. The dried pellets are then fed into a hopper, where they are transported to the molding machine via a screw conveyor. For products requiring specific colors or functional additives (e.g., UV stabilizers, flame retardants), masterbatches or additives are blended with the base resin at precise ratios during this stage.

2. Mold Design and Fabrication

Molds are the core tooling that dictates the shape, size, and surface finish of plastic products, and their design is tailored to the chosen molding process and product specifications. For injection molding—the most widely used technique for high-volume production—molds consist of two main halves: the cavity (which forms the outer surface of the product) and the core (which shapes the inner structure). Mold designers use computer-aided design (CAD) software to create detailed models, and computer-aided manufacturing (CAM) tools to fabricate molds from high-strength steel or aluminum, ensuring tight tolerances for precision parts.

For specialized products, molds may include additional features such as sliders for undercut geometries, ejector pins for product removal, and cooling channels to regulate mold temperature and reduce cycle times. Prior to mass production, prototype molds are often used to validate design feasibility and address potential issues like warpage or filling defects.

3. Molding Process

Injection molding is the dominant molding method for plastic products, ideal for producing consistent, complex parts in large quantities. The process begins with the resin pellets being melted in the molding machine’s barrel via heat and shear force from the rotating screw. Once the molten plastic reaches the optimal viscosity, it is injected into the closed mold cavity at high pressure (typically 100–200 MPa) to ensure full cavity filling.

After the plastic cools and solidifies in the mold (a stage controlled by the cooling channels), the mold opens, and ejector pins push the finished part out. Other common molding processes include blow molding for hollow products (e.g., bottles and containers), extrusion for continuous profiles (e.g., pipes and films), and compression molding for thick, rigid components (e.g., automotive panels). Each process is selected based on the product’s geometry, volume, and material characteristics.

4. Post-Processing and Finishing

Most plastic products require post-processing to meet final quality and aesthetic standards. Trimming removes excess material (e.g., injection gates or flash) using automated cutters or manual tools, while deburring eliminates sharp edges for user safety. For products with decorative or functional requirements, additional finishing steps may include:

• Painting or printing: Applying coatings or graphics for branding or corrosion resistance

• Assembly: Joining multiple components via ultrasonic welding, adhesive bonding, or mechanical fasteners

• Polishing or texturing: Enhancing surface smoothness or adding tactile finishes

• Thermal treatment: Relieving internal stresses to improve dimensional stability

5. Quality Control and Inspection

Quality control is implemented at every stage of production to ensure compliance with design specifications and industry regulations. Incoming raw materials are tested for melt flow index (MFI) and purity, while in-process inspections monitor mold temperature, injection pressure, and cycle time to maintain consistency. Post-production, finished products undergo dimensional checks using coordinate measuring machines (CMMs), visual inspections for surface defects, and mechanical testing (e.g., tensile strength, impact resistance) to validate performance.

For products used in regulated industries (e.g., medical devices or food packaging), additional testing for biocompatibility, chemical resistance, and food safety compliance is mandatory before the products are approved for market distribution.

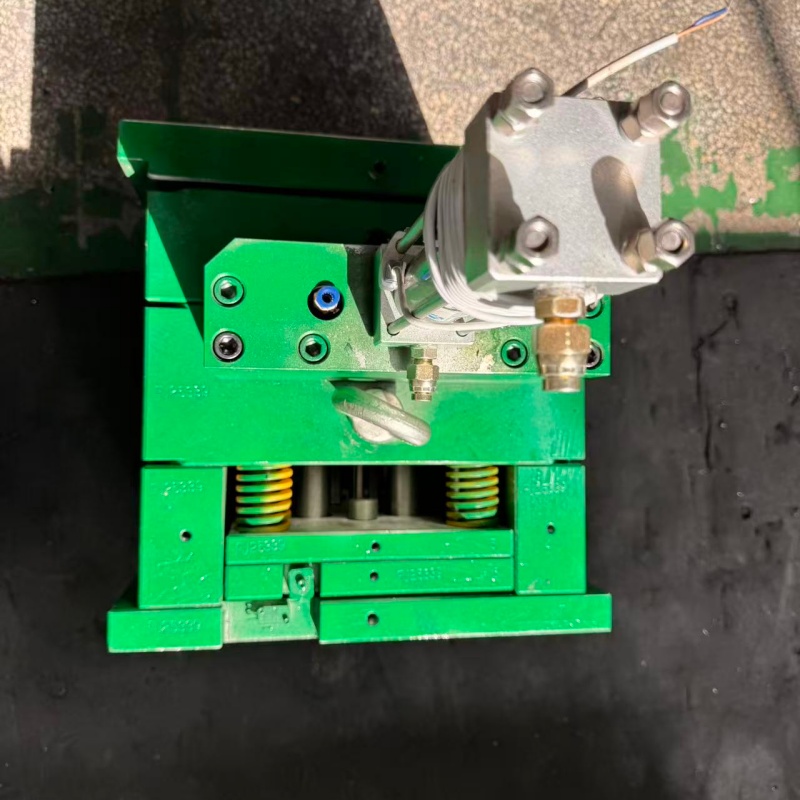

We'll spray color on mold surface for rust protection

Product Specification:

Stainless Steel Medical Injection Molding Companies | |||||||

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | mould manufacturer | 2 | S136 | 45# | 45days | 400000 | 40 |

Other plastic injection mould products we make for customer

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom.